Published on behalf of members of NCIA’s Cannabis Manufacturing Committee

We stand at a pivotal juncture in the cannabis industry, defined by rapid technological advancements in extraction methods and an increasingly complex regulatory landscape. How do we make sense of it all? Before you can have consumables, topicals and concentrates, you must first extract the cannabinoids from the plant. There are multiple extraction methods available, and each method not only influences the efficiency and cost of production, but also affects the purity, potency, and safety of the final product. Manufacturers of cannabis products use various methods for extracting vital compounds from cannabis. Keep on reading to dive into the multifaceted world of cannabis extraction, exploring traditional, modern, and emerging technologies that are shaping the industry.

Understanding Extraction Methods

Here’s a look at some of the most common technologies used:

- Traditional and Solvent-Based Extraction

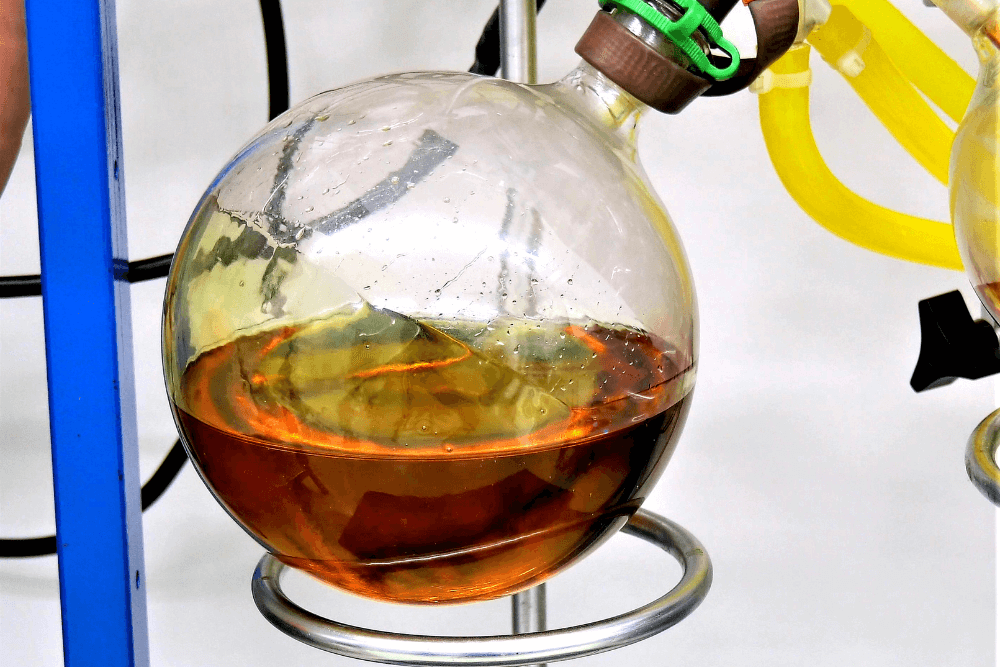

- Butane Hash Oil (BHO) and Ethanol Extractions: These are among the most prevalent methods, prized for their efficiency and ability to preserve terpenes. However, solvent-based methods require rigorous disposal of the solvent post-extraction to avoid contamination, highlighting the necessity for strong quality-control measures.

- CO2 Extraction: Utilizing supercritical CO2 as a solvent, this method is celebrated for its safety and environmental friendliness. The precision and adjustability of CO2 extraction allow for targeted extraction of specific cannabinoids and terpenes, but at a higher operational cost.

- Physical and Non-solvent Extraction Techniques

- Rosin Tech and Ice Water Hash: These solventless techniques are gaining traction for their simplicity and the purity of the extract. While they offer a safer alternative by eliminating solvent residues, their scalability and efficiency in commercial settings remain areas for development.

- Novel Extraction Innovations

- Ultrasonic Extraction and Microwave-assisted Extraction (MAE): The cutting edge of extraction technology, these methods promise increased efficiency, reduced processing times, and enhanced terpene profiles. Their adoption is set to revolutionize the industry, provided they can overcome initial high capital investment barriers and integrate seamlessly with existing regulatory frameworks.

Product Quality and Regulatory Compliance

Which extraction method you choose will directly affect the chemical composition of the final product, and advanced testing and quality assurance protocols will be necessary. The industry has seen significant advancements in testing technologies, such as High Performance Liquid Chromatography (HPLC) and Gas Chromatography-Mass Spectrometry (GC-MS), which are crucial for verifying the absence of solvents, pesticides, and other contaminants.

Navigating the regulatory landscape is a formidable challenge for manufacturers. Regulations vary widely across jurisdictions and often lag behind technological advancements. Be sure to understand issues such as labeling requirements, potency limits, and compliance with Good Manufacturing Practices (GMP).

Manufacturing Challenges and Best Practices

Lab Safety and Employee Training

- The extraction process involves handling volatile substances and operating complex machinery, so robust lab safety protocols and ongoing employee education are must-haves. Prioritize creating a culture of safety and compliance, such as creating SOPs for your processes. This will help prevent accidents and ensure the well-being of your staff. Also be sure to document training and day-to-day operational issues.

Scaling Production While Maintaining Quality

- As the demand for cannabis extracts continues to grow, you might face the challenge of scaling your operations without compromising on product quality. You can achieve this balance by implementing scalable extraction technologies, maintaining stringent quality control, and investing in research and development.

Recommendations for Industry Growth and Policy Reform

- Foster Innovation through Research and Development: Public and private investment in research can help identify new extraction technologies and their applications.

- Harmonize Regulatory Standards: The standardization of safety and quality regulations across jurisdictions will facilitate compliance and ensure a level playing field.

- Promote Consumer Education: Comprehensive educational initiatives will inform consumers about the safety, efficacy, and benefits of cannabis extracts.

- Engage in Policy Dialogue: Active dialogue between industry stakeholders and policymakers will ensure that common-sense regulations are informed, pragmatic, and open to innovation.

The demand for infused products is growing, so manufacturers need to be planning for advanced extraction technologies – ones that fit within regulation and prioritize safety, quality, and consumer protection. By embracing innovation, advocating for harmonized regulations, and educating an informed consumer base, we can achieve growth and establish ourselves as a responsible and valuable sector of the global economy.

Follow NCIA

Newsletter

Facebook

Twitter

LinkedIn

Instagram

–