Written by: Karen Quinto, MS Environmental Science, Willow Industries

Balancing Protection, Sustainability, and Safety in the Packaging Industry

In 2012, child-resistant packaging legislation prevented access to children while the legal cannabis market began to open up but the issue persists over a decade later and the topic is still controversial to some.

“CR [Child-resistant] packaging on flower products makes no sense. On edibles sure, but flower? Not to mention that alcohol has no CR, and I’d argue is 100x more harmful to a kid who gets into it…. It feels like a piece of legislation to make regulators feel good about themselves but is a frustration to everyone else,” voiced Tyler Works on his LinkedIn page.

Works, the Director of Account Management for Cannabiz Media, is not alone on this sentiment. The delicate balance between protecting products and ensuring consumer safety is continuously challenged by concerns over its efficacy and common sense.

“When we worked on these rules, this was considered but it was more important to satisfy the minds of the people terrified of kids getting into cannabis,” chimed Gus Green, who helped states adopt the Code of Federal Regulations for the Poison Prevention Packaging Act due to cannabis being a Schedule 1 drug, therefore automatically deemed harmful to children. “Now is a better time to breach the subject. The Poison Prevention Packaging Act states that any product deemed toxic for a child under 5 years old should be in child- resistant, and senior-friendly packaging. I worked with state agencies around the country to adopt these. The rule is a bit more specific than that if you dive in though, it’s about the ability for a child to ingest a toxic amount within a specific timeframe…[For example] travel-size Listerine bottles are not always CR, but the large bottles are always CR.My specialty was child-resistant, or specialty packaging. Packaging specialists should be the ones rewriting these rules but I often see committee members with no background in the field attempting to write them.”

CFR 16 PART 1700 refers to Title 16, Part 1700 of the Code of Federal Regulations (CFR), which specifically deals with Poison Prevention Packaging. This regulation focuses on the packaging requirements for substances that are potentially hazardous or poisonous, especially to children. The key objective is to prevent accidental ingestion by children and reduce the risk of poisoning incidents.

The regulation outlines standards and specifications for packaging design and labeling to ensure that products posing a poisoning risk are packaged in a way that makes it difficult for children to open or access the contents. This includes child-resistant closures and barriers to entry. The goal is to enhance the safety of household products, medications, and other substances that could be harmful if ingested by young children. Compliance with CFR 17 PART 1700 is essential to meet safety standards and protect consumers, particularly children, from accidental poisoning.

It seems straightforward enough but there are many problems inherent in adopting a rule that was not specifically made for the cannabis industry.

The Dose Makes the Poison

Works’ earlier sentiment is essentially that “the dose makes the poison”. This fundamental concept in toxicology states that any substance can be harmful in large quantities but may be safe at lower levels.

Proponents of this sentiment argue that cannabis flower contains THCA, which is a non-psychoactive cannabinoid, meaning it does not produce the “high” associated with THC and cannabis use. THCA is a precursor to THC through decarboxylation, which converts THCA to THC with the application of heat, typically when it is smoked, vaporized or cooked. Therefore, ingestion of THCA is unlikely to cause intoxication in a child. Moreover, Works argued that requiring child-resistant packaging for THC flower is inconsistent with the treatment of other potentially harmful household items that are not subject to the same level of regulation, such as bottles of alcohol that do not require child-resistant packaging despite their inherent availability and quantity in a household.

Advocates for the deregulation of child-resistant packaging of flower might suggest that just like for alcohol, home environment control would suffice in controlling cannabis as a safety measure for children. Storing THC flower in an inaccessible location followed by strong educational measures urging parents to responsibly store and prohibit access could be effective in preventing accidental ingestion.

While these points are presented for the sake of argument, it’s important to reiterate that child-resistant packaging regulations are designed to prioritize child safety. The potential risks associated with accidental ingestion of THC or other substances are serious, and any discussion around exemptions should carefully consider the well-being of children. Public health and safety regulations are typically enacted with the aim of preventing harm and protecting vulnerable populations. But this is not the only issue people have in mind regarding packaging.

Child-resistant packaging for flower not only seems problematic because it is incongruent with regulations for other harmful household substances including alcohol but also because it creates trash. A lot of it.

The Single-Use Abuse

The Sustainable Cannabis Coalition estimated that in 2020, the US Cannabis Industry used almost one billion pieces of single-use plastic that mostly ended up in landfills. Research and testing activities–including those for the cannabis industry–adds up to over 12 billion pounds per year. The majority of these plastics cannot be recycled due to their diverse material composition. A whopping 40% of total emissions are attributed to our procured goods and services.

Packaging materials, particularly plastics, are composed of various substrates such as polyethylene, each with distinct properties. Sustainability concerns arise as certain laminated plastics prove difficult to recycle. Challenges persist, especially in the context of single-dose packaging and restrictions on child-resistant reclosable plastics.

“People want to recycle bioplastics but they don’t have good barrier properties,” Gus Green states. “There is also a problem with the idea of biodegradables because they are designed to break down. Biodegradable plastic is not allowed in child-resistant reclosable plastics because the mechanism will fail because the material is frail, but laminated plastics that have great barrier properties cannot be recycled.”

The Sustainable Cannabis Coalition blog announced that in 2021, CULTA, a cannabis company, partnered with The High 5 Initiative, a non-profit company that’s working to keep Polypropylene #5 plastics out of landfills through recycling. Patients can return packaging to CULTA, where the initiative team sorts and processes the materials, recycling over 95% and transforming #5 plastics into Post Consumer Resin (PCR) for manufacturing other products.

Despite the environmental benefits, transitioning to eco-friendly packaging faces challenges, including cost implications. For instance, CULTA notes that switching to eco-friendly cellulose packaging would increase costs, making it economically challenging for cannabis companies, coupled with perceived quality issues with thinner and more pliable cellulose bags (which may seem cheaper, thus impacting consumer acceptance).

The Future of Plastic Waste in Cannabis

New metalized child-resistant compostable cellulose film bags have entered the market for the first time and offer the opportunity for both home and industrial composting, including the cannabis industry.

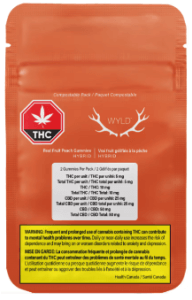

“In Canada, Wyld has adopted child-resistant compostable pouches. Many edibles brands are moving to an inner-outer pack combo with individually-wrapped pieces inside a mother bag, similar to many traditional candies. Think caramels, Starburst, cough drops, Hershey’s Kisses, Reese’s cups, etc. – cannabis consumers want fresh products, and individual wraps accomplish that. To avoid more single-use plastics, NatureFlex is seeing significant, promising interest,” Elisha Hedin, a regional sales manager from Futamura, manufacturer of NatureFlex explained. “Compostable films can actually have a very good barrier and NatureFlex is an ideal packaging material for both gummies and flower. There’s a perception in the industry that compostable materials are low quality and that’s simply not true.”

Wyld, a Climate Neutral Certified brand, offers the cellulose-based packaging made from cellulose film laminated to a biosealant for their gummies. In home composting, this metalized compostable film degrades completely in 12-16 weeks. In industrial settings, it takes twice as fast to convert the cellulose into water, CO2, biomass, and mineral salts in just 6-8 weeks.

Meanwhile, in the research industry, Polycarbin has touted itself as the world’s only circular economy for single-use lab plastics. This California-based company helps labs achieve their sustainability goals by diverting these valuable materials from landfills and incinerators into the next generation of low-carbon lab products.

“Much like with food-tech and biotech, the cannabis industry is driven by a growing dependence on single-use plastics. From the harvest fields to the QC and QA laboratories, it is more important than ever that this industry consider the carbon footprint associated with its supply chain,” James O’Brien, CEO of Polycarbin emphasized. “Through responsible waste stream management and sustainable procurement, the cannabis laboratories can significantly attenuate the environmental impact of a major source of its scope three emissions—fossil fuel-derived, single-use plastics.”

As the packaging and research industry grapples with the complex interplay of material properties, sustainability challenges, and stringent safety standards, a delicate balance must be struck. Navigating the evolving landscape requires continuous innovation, collaboration, and adherence to regulations, ensuring that the packaging not only safeguards products but also contributes to a sustainable and secure future.

Follow NCIA

Newsletter

Facebook

Twitter

LinkedIn

Instagram

–