Member Blog: The Importance of Storing Cannabis Properly

Cannabis is affected by humidity.

Yes, cannabis is definitely affected by humidity. Cannabis plants are sensitive to changes in temperature and humidity levels, both during cultivation and after harvesting.

During cultivation, cannabis plants need a specific range of temperature and humidity levels to thrive. Too much humidity can lead to the growth of mold and mildew, while too little humidity can cause the plants to dry out and become brittle.

After harvesting, cannabis buds need to be dried and cured to preserve their quality and potency. During this process, it is important to control the humidity levels to ensure that the buds dry slowly and evenly. If the humidity levels are too high, the buds can become moldy, while if they are too low, the buds can dry out too quickly and lose their potency.

In addition, the humidity level can also affect the storage of cannabis. If the humidity levels are too high, it can cause the buds to become moldy, while if they are too low, it can cause the buds to become brittle and lose their flavor and potency.

Therefore, it is important to control the humidity levels during the cultivation, drying, curing, and storage of cannabis to ensure that the buds are of high quality, potent, and safe for consumption.

How can dry cannabis lose potency?

When cannabis is dried and cured, it naturally loses moisture. However, if the cannabis becomes too dry, it can begin to lose potency.

This is because the active compounds in cannabis, such as THC and CBD, are stored in the trichomes on the surface of the buds. When the buds become too dry, the trichomes can become brittle and break off, causing the loss of these valuable compounds.

In addition, when cannabis becomes too dry, it can also affect the flavor and aroma of the buds. The terpenes, which are responsible for the characteristic smells and tastes of different strains, can degrade over time if the buds are too dry.

Therefore, it is important to store cannabis at the correct humidity levels to ensure that it stays fresh and potent. The ideal humidity range for storing cannabis is between 59% and 63% relative humidity. If the buds become too dry, you can try to rehydrate them by adding a humidifying device, such as a moisture pack, to the storage container. However, it is important to be careful not to add too much moisture, as this can cause the buds to become moldy or develop other quality issues.

Cannabis potency versus humidity

The potency of cannabis can be affected by humidity levels. When cannabis is stored at a high humidity level, it can cause the breakdown of THC and other cannabinoids, decreasing potency. On the other hand, if cannabis is stored at a low humidity level, it can cause the buds to become dry and brittle, which can also lead to a decrease in potency.

Therefore, it is important to store cannabis in a controlled environment with the appropriate humidity level. This can be achieved using specialized storage containers, such as airtight jars or humidors, designed to maintain a consistent humidity level. It is also important to monitor the humidity levels regularly and adjust as necessary to ensure that the cannabis stays fresh and potent.

Cannabis taste versus low humidity

When the terpenes are lost, the flavor of the cannabis can become harsh, bitter, or stale. This can make the smoking experience less enjoyable and may also indicate a decrease in potency.

If the buds have become too dry, it is possible to rehydrate them by adding a humidifying device, such as a moisture pack, to the storage container. However, it is important to be careful not to add too much moisture, as this can cause the buds to become moldy or develop other quality issues.

Committee Blog: VPD Topics for Cannabis Cultivation and Opportunities to Reduce Facility Energy Costs

by NCIA’s Facilities Design Committee

by NCIA’s Facilities Design Committee

Indoor cannabis cultivation facilities are complex environments, where a large number of variables interact to create an ideal ecosystem to grow cannabis. The upside of an indoor facility is it allows a year-long growing climate, optimized for each stage of the plant grow cycle. The downside, however, is creating this ideal climate is very energy-intensive.

There are three (3) main types of precision cooling equipment offered in the cultivation space. Those are Air Cooled DX, Water Cooled DX, and Chilled Water Units. DX stands for direct expansion systems. The immediate and most noteworthy difference between these systems is that DX units cool air using refrigerant, and Chilled Water units cool air utilizing chilled water. A DX unit uses refrigerant-based cooling and cools indoor air using a condensed refrigerant liquid. Typically, the decision regarding which cooling source is better for a cultivation facility is usually driven by the size of the cooling plant as well as other unique site conditions. Selecting the right HVAC system for your cultivation facility can be a challenging process driven by many factors, however this is beyond the topic of discussion for this article, it should be noted that the following analysis assumes an Air Cooled DX based system.

The total energy costs for indoor cannabis grow operations typically vary between 25%-50% of total operating costs (or approximately 150-200 kWh/sq.ft). In comparison, energy use in a typical commercial building environment is approximately 25 kWh/sq. ft. As indoor cultivation facilities increase, they can be a source of strain on electrical grids. A recent study showed indoor cannabis cultivation alone accounted for 4% of the energy grid usage in Denver. (IEEE, 2020)

With that context, any areas we can identify to improve energy efficiencies without introducing a negative impact to the grow environment can have enormous bottom-line impacts for cultivation owners and society at large.

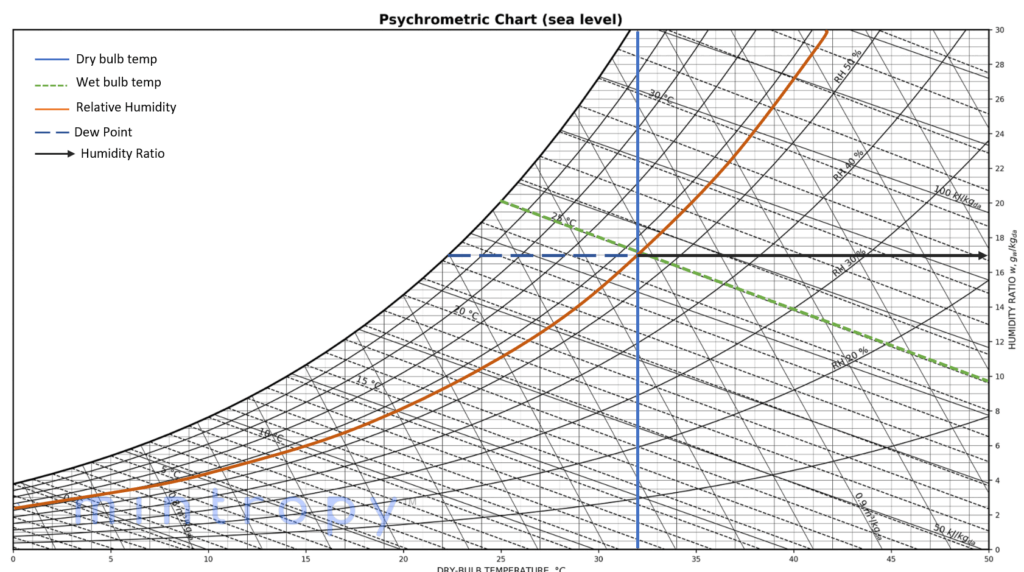

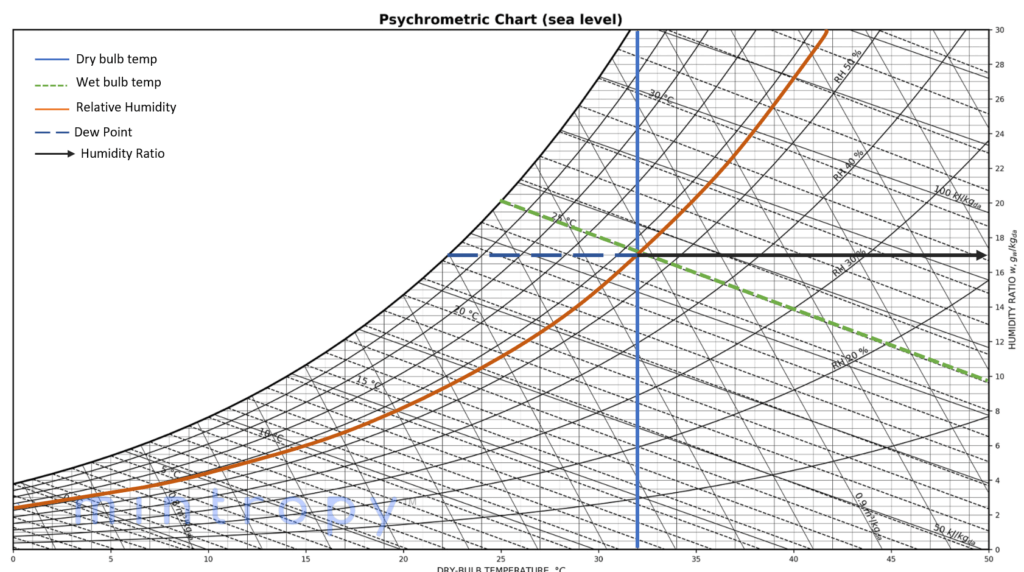

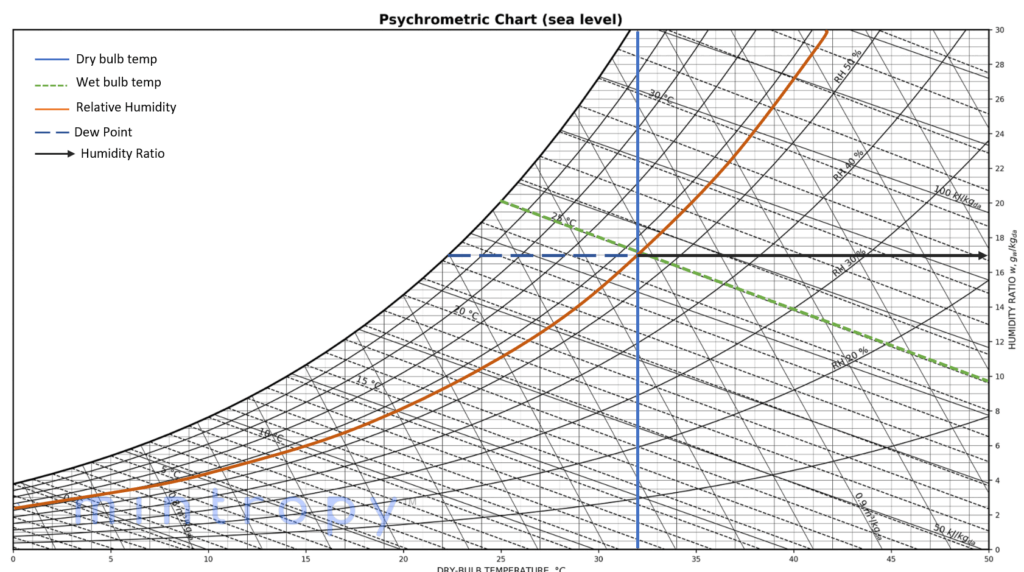

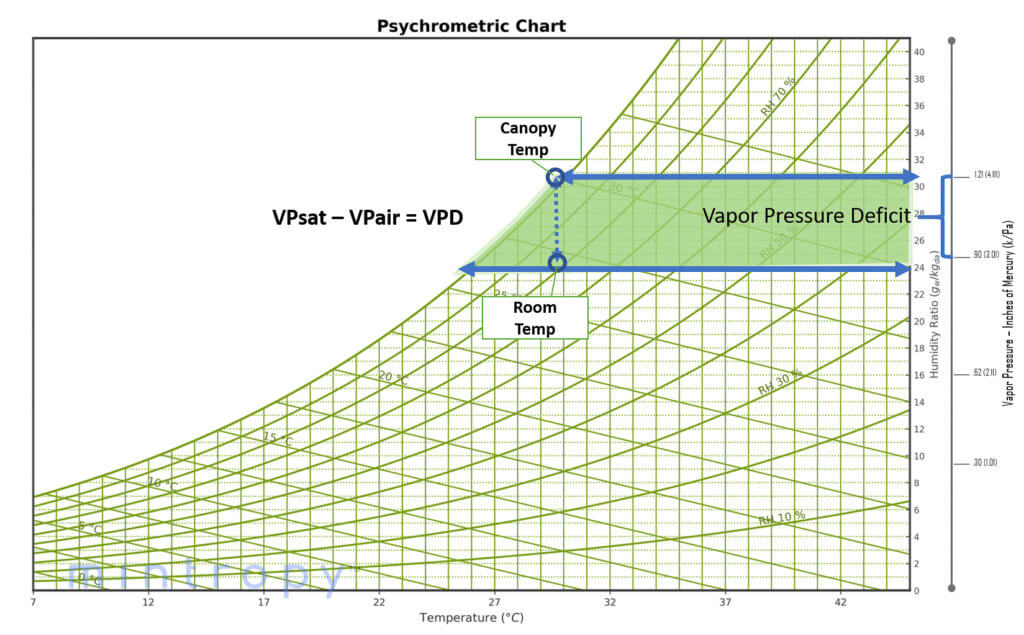

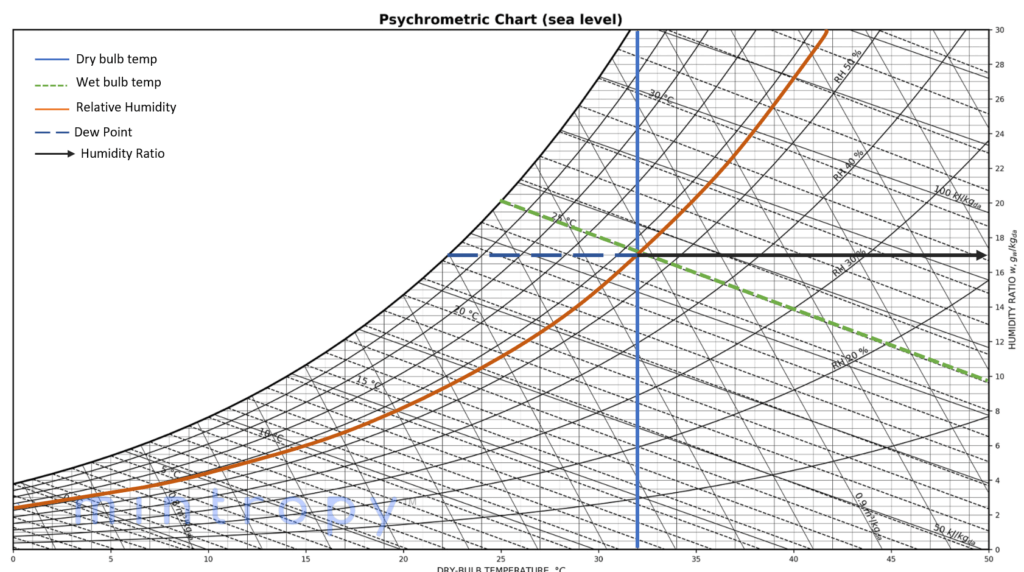

In this article, we are going to be examining two ways we can optimize HVACD systems to improve energy efficiency. When HVACD systems are designed for grow facilities, the primary variables we are looking to influence are the following psychrometric properties: temperature (either wet or dry bulb) and relative humidity. Mechanical engineers will often refer to an information-packed graph called a psychrometric chart shown below.

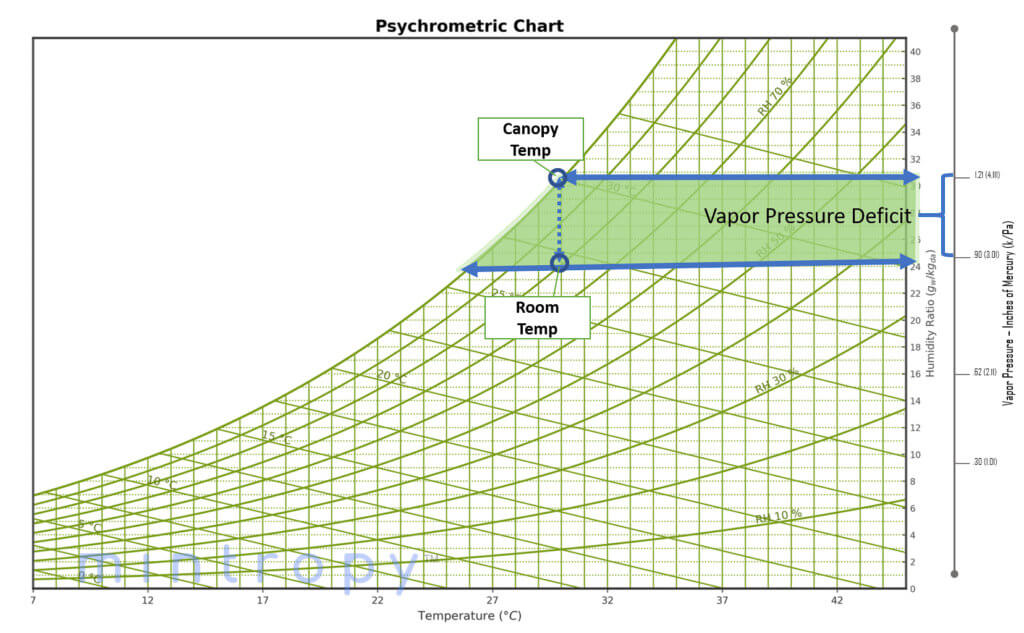

This chart helps to visualize the relationships different properties of air like temperature, humidity (relative and absolute) and dew points along the saturation curve have with each other. This is useful to analyze, as these are direct inputs to a scientific measure often favored by growers called Vapor Pressure Deficit (VPD).

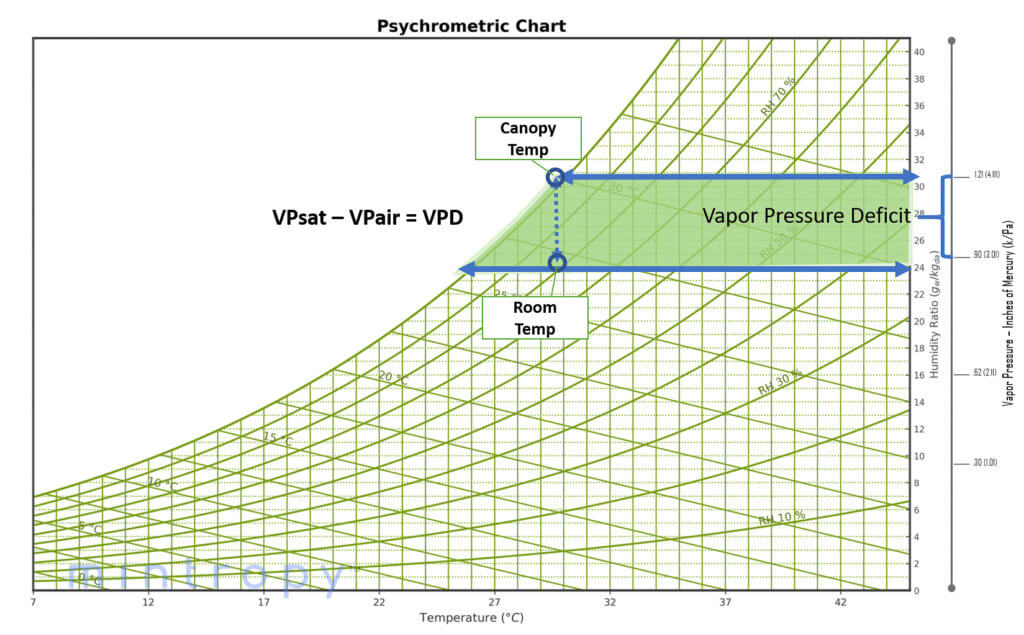

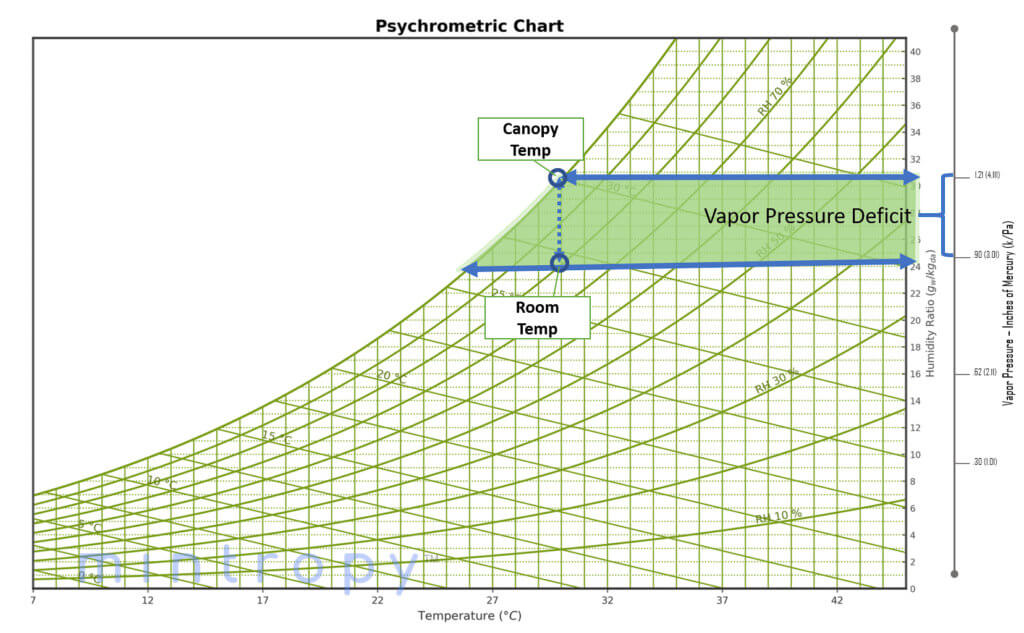

Vapor Pressure Deficit, simply described, compares these variables to determine how much additional room for water vapor there is in the air. This is important as it determines how readily cannabis plants can transpire. Controlling transpiration rates help to aid in healthy, robust growth through the plant life cycle. Growers tend to want lower VPD, and thus lower transpiration, early in plant maturity, and increase to higher VPDs, and thus high transpiration, at the flowering stage before harvesting.

So we know a successful indoor cultivation facility HVAC system will need to control temperature and humidity to ensure the desired VPD values. How can we do that efficiently?

Stand-Alone Dehumidifiers Are Inefficient

A cannabis plant can transpire up to 99% of the water absorbed through its roots. Due to this, we often tell people that designing an indoor cultivation facility is like designing a data center with a swimming pool inside. Because of the increased humidity introduced from plant transpiration, we must pay special attention to dehumidification strategies within the grow space. Humid air requires treating significant latent loads in the grow space, requiring additional energy to remove moisture from the airstream. This is one reason HVACD systems can consume up to 50% of the energy budget in a cultivation facility. As previously mentioned, higher humidity levels will lower the VPD in the room, preventing a plant from transpiring effectively to continue healthy growth. To combat this, sometimes stand-alone dehumidifiers are added into the grow room.

While these units can do the job of removing moisture from the room, it is a very energy-intensive process. One of the issues with stand-alone dehumidifiers is that they reject heat back into the grow room, thereby adding additional cooling load onto the main HVAC equipment.

Integral Hot Gas Reheat System

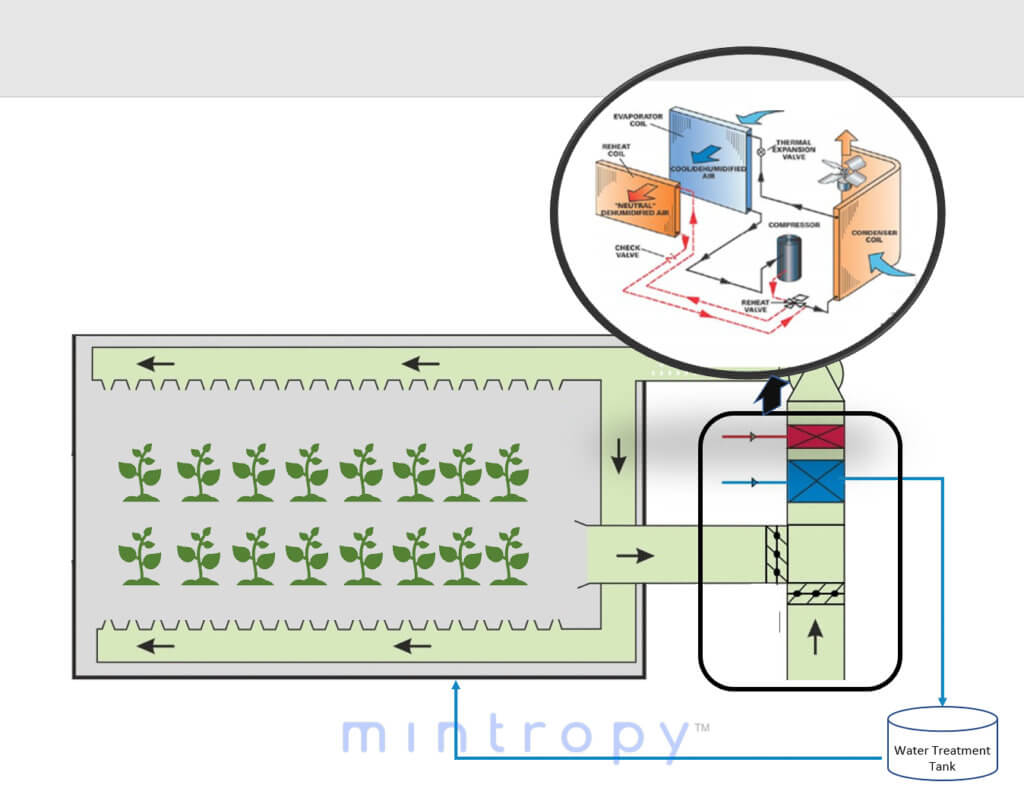

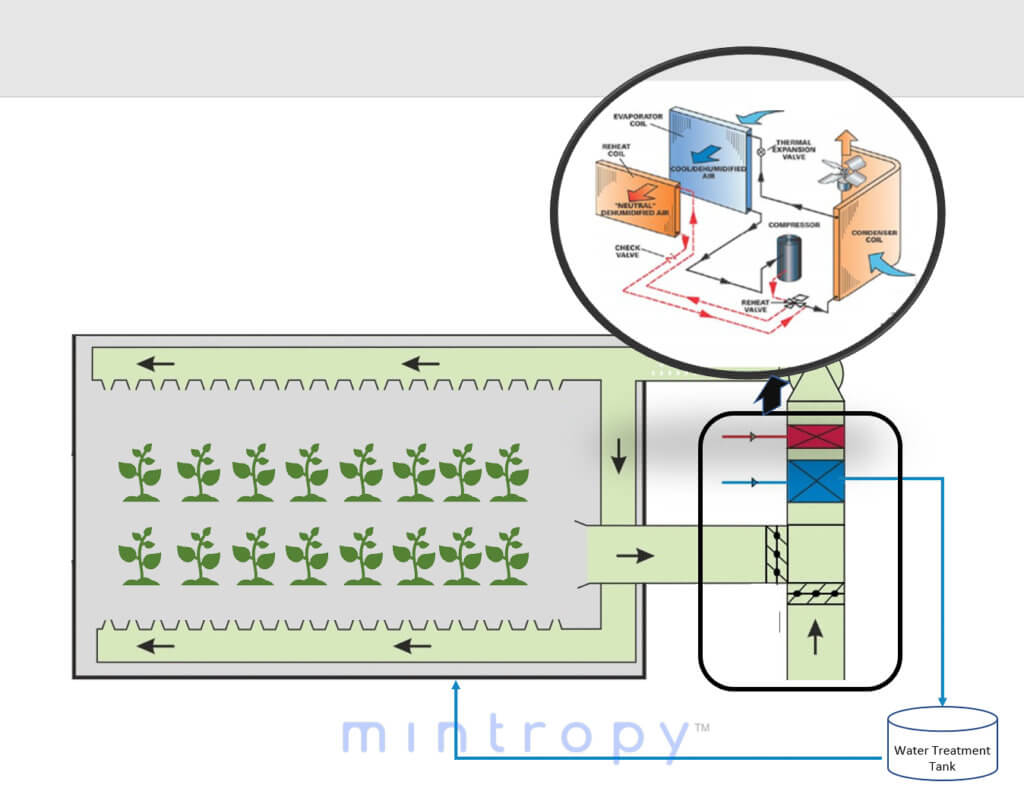

An air handling unit, sometimes called an air handler or AHU, is a piece of equipment that is used to condition and circulate air as a component of a heating, ventilating, and air conditioning system.

The air handler is usually a large metal box that contains a blower, heating and cooling elements, filter chambers, sound attenuators, and dampers. It then connects to ductwork that distributes the conditioned air throughout the space before returning it back to the AHU.

Of particular interest are the units cooling coil and reheat coil. These two components are namely responsible for controlling VPD levels in our grow space. In an AHU equipped with Integral Hot Gas Reheat, the cooling coil serves as a dehumidifier, by cooling the air thereby reducing its moisture/latent load (we recommend considering capturing this water for treatment and reuse: read more here). The hot gas reheat capability utilizes heat from grow space and compressor heat to reheat the air before returning to the grow space (without using additional heating energy).

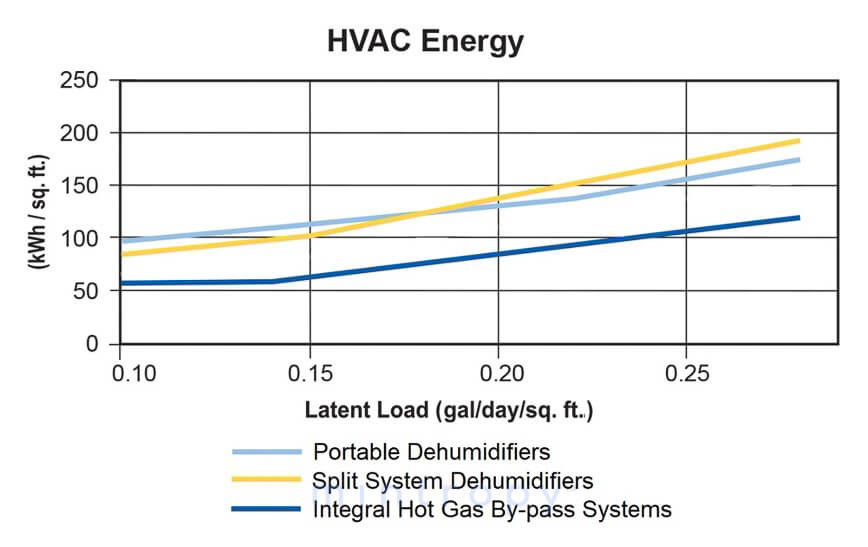

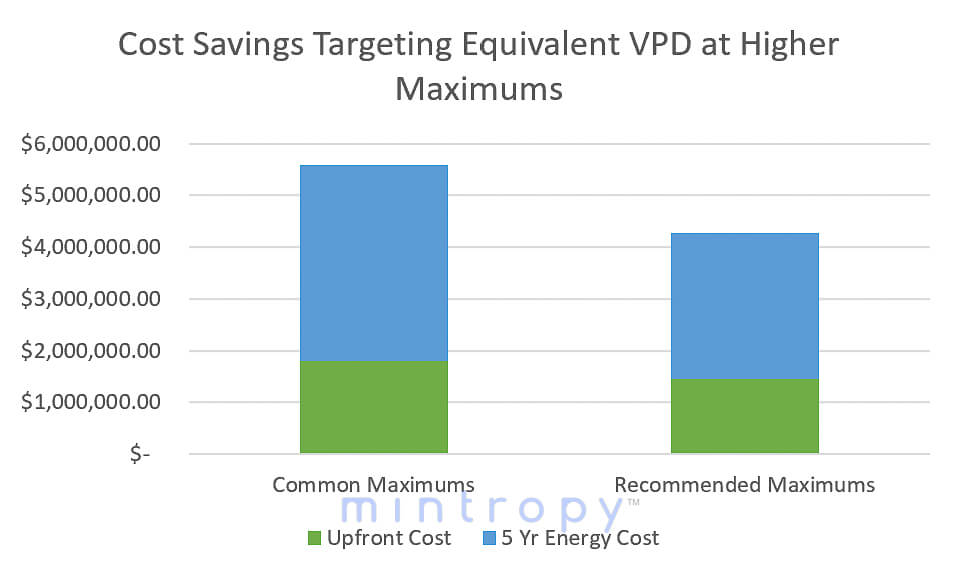

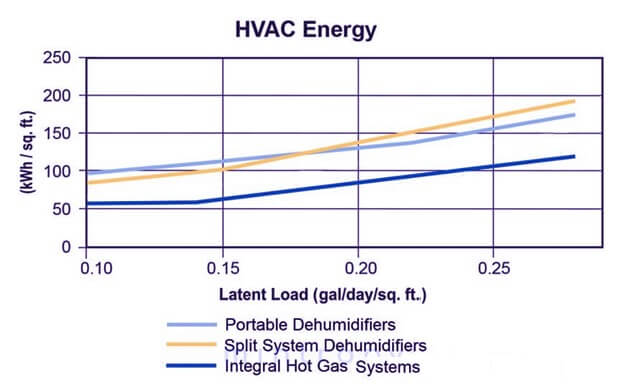

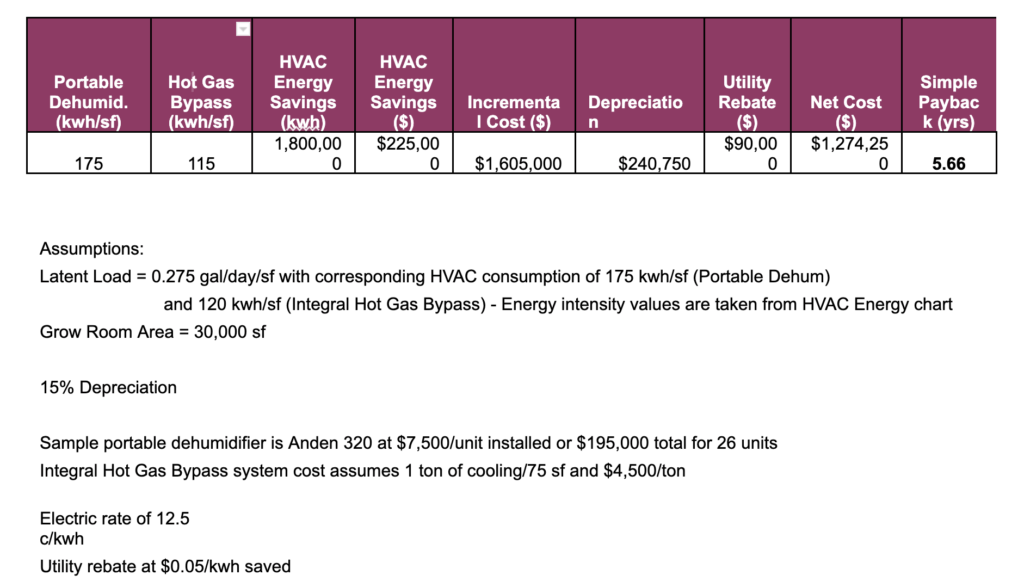

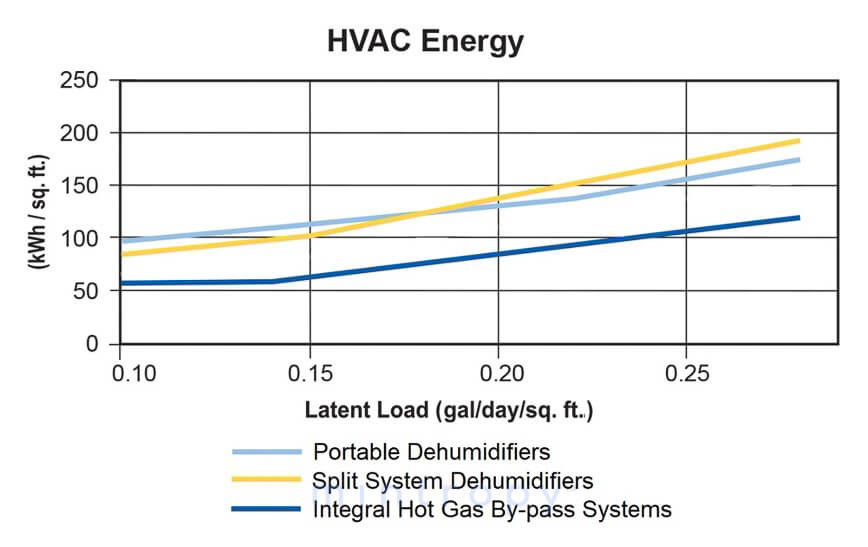

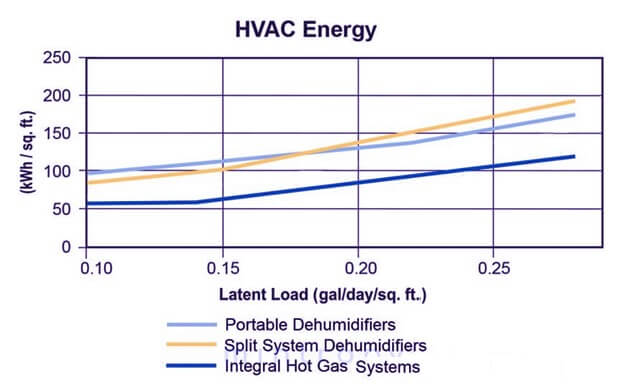

While this may seem like a minor design change, it results in a considerable reduction in energy. As the chart below illustrates, leveraging Integral Hot Gas Reheat units can result in a 30-35% reduction in HVACD energy when compared with other dehumidification systems. Additional automation capabilities built-into these systems will ensure that the grow room will remain tightly controlled within the desired state points of your grow room to optimize VPD.

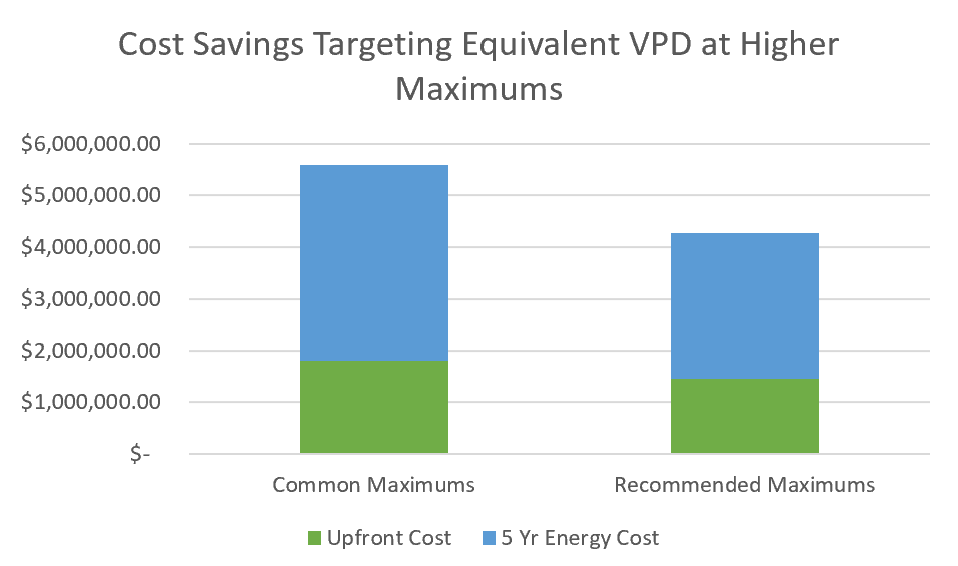

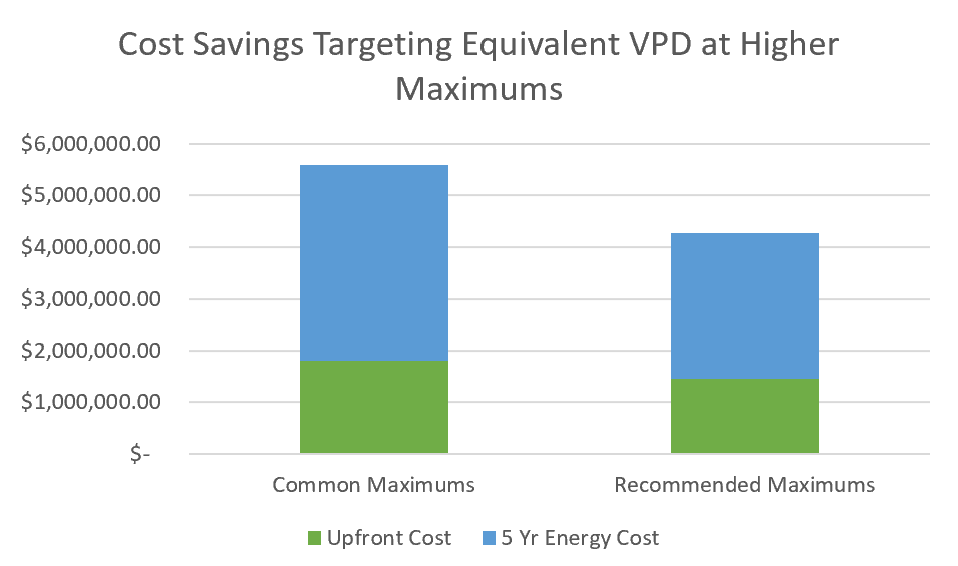

This reduction in energy quickly adds up to reduced utility bills. Despite marginally higher upfront costs as compared to standard HVAC equipment coupled with standalone dehumidifiers, this option results in a lower 5-year system cost than common HVACD systems installed in cultivation facilities, and these savings will only increase over time.

Maintaining Consistent VPD, but at higher Temperature / Humidity Ranges

The second energy-saving measure we would like to discuss goes back to the earlier discussion of VPD. Recall the equation for VPD is

V P sat – V P air = VPD

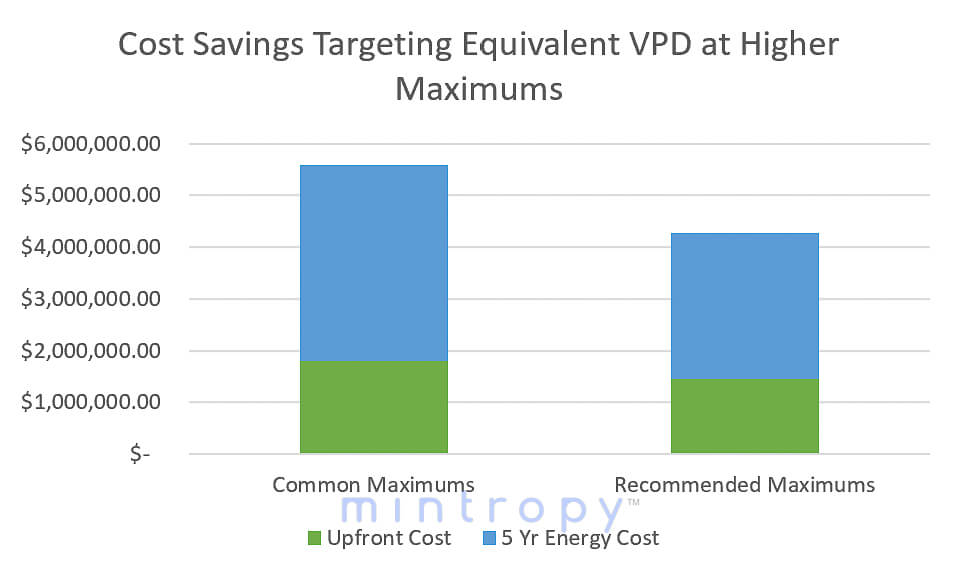

This is important, as it provides growers the flexibility to fall within desired VPD ranges, but at higher temperature and humidity ranges than typically used. Many growers target grow room setpoint temperatures around 72-75F and limit relative humidity to a maximum of 50 percent, but by allowing slightly higher room setpoint temperatures of 76-82F, with corresponding relative humidity increases, we can create identical VPDs at higher setpoint temperatures. The cost-benefit of this small adjustment is considerable. The HVAC system (including cooling and dehumidification) can be sized at roughly 20-30% smaller capacity, reducing the owner’s up-front equipment costs. In addition, the system’s energy consumption and costs during operations will be significantly lower, to the tune of 30-40%. In a theoretical 30,000 square foot facility, this could result in $1,125,000 savings in the first 5 years.

The case for a hybrid greenhouse, using VPD controls

Another way of growing instead of full indoor, is a highly efficient, sealed greenhouse. It is designed to maximize sunlight inside the growing environment, meaning energy used for lighting is dramatically reduced. And because it is sealed, energy-efficiency is maximized, as leakage is kept to a minimum. In order to make this work, these greenhouses need to be hybrid (using insulated walls and glazing) and the orientation and design play a bigger role.

In this hybrid greenhouse environment, the growing space typically heats up as soon as the sun comes out, no matter the outside temperature. Cooling in this instance would increase the power usage vs. increasing the humidity to keep the VPD level in the same range. When the sun goes down, the opposite happens. The grow environment starts to cool and it would be expensive to try and keep the temperature up.

In order to achieve VPD control, the control system needs to be able to variably adjust temperature and humidity, based on inputs like weather forecast, time of the day, day of the year, etc. Being able to control the grow environment by VPD level will significantly reduce the energy consumption for your HVACD system.

Member Blog: Eradicating Pesticide Use in the Cannabis Industry – Without Sacrificing Crop Quality

By Carlos Perea, Co-founder and CEO of Terra Vera

One of the direst, yet infrequently discussed, issues in the cannabis industry is the lack of federal guidelines regulating pesticide use. Despite the adult-use cannabis market consistently expanding on a state-by-state basis, as long as the crop remains illegal on the federal level, much-needed national oversight will continue to be limited.

The more states that legalize under a national prohibition, the more varying and convoluted state-by-state crop management regulations may become. Meanwhile, without standards firmly set in stone across the country, some cultivators have turned to hazardous chemicals to control pathogens and preserve their crop yields. Such cultivation solutions can compromise the safety of staff, the environment and, of course, the consumers.

Health Hazards of Pesticides in Cannabis

Even when shopping at a licensed adult-use or medical dispensary, consumers today still cannot be 100 percent confident that the cannabis they are purchasing is completely safe and free of contaminants and unwanted components, such as pesticides, harmful microbials, heavy metals, and solvents. Emerging research from Colorado State University shows that contaminants in cannabis, including pesticides, “are imminent threats that directly impact public health and wellness, particularly to the immunocompromised and pediatric patients who take cannabis products as a treatment for numerous human disorders including cancer patients and those suffering from epileptic seizures.” With many consumers turning to cannabis for its health benefits, and because it’s a natural alternative to heavily processed pharmaceuticals, the cultivation process should honor cannabis’ medical use by being as safe and accountable as possible.

The pesticide issue is compounded when we think about how cannabis is often consumed: through inhalation. Additional research has shown that nearly 70 percent of the pesticides used in cultivation remain in the cannabis flower that consumers smoke.

Even when these same pesticides are permitted in other types of American agricultural industries, this is a global anomaly. More than 25 percent of pesticides used in the U.S. are banned in other countries.

Moving Towards a Pesticide-Free Flower

So how do we work towards a pesticide-free cannabis industry? Licensed businesses, regulators, and consumers need to band together to set standards and guidelines for pesticide use across each legal state, and eventually on a federal level.

In 2020, Arizona took a page out of Oregon’s playbook by establishing a regulatory agency and adopting Oregon’s standards for limiting pesticide use in cannabis, setting a prime example for inter-state collaboration and accountability. Measures also need to be taken to lower the cost of testing cannabis products for pesticides and contaminants. And, of course, we need to embrace more sustainability and environmentally-minded education, and emerging technologies.

While testing does not necessarily prevent contaminants during the grow process, frequent, reliable, and standardized testing can help ensure contaminated products don’t make it to market. Unfortunately, testing requirements continue to differ by state, with some being more lenient than others. For instance, certain states only test for certain types of microbials, while others allow companies and cultivators to cherry-pick samples. This makes it easier for companies’ products to meet compliance, however, doesn’t ensure that the final products available for purchase will be safe for the consumer. Looking ahead towards inevitable federal legalization, testing requirements need to be uniform across all legal markets.

However, cultivators shouldn’t wait for federal oversight to hold themselves to the highest possible standards. There are inexpensive testing procedures currently available that cultivators can adopt before sending their cannabis products to the lab, which can help to better ensure what they are doing is working and catch a problem before it starts.

There are also non-toxic crop management technologies available now, and in addition to seeking out vendors offering innovation-driven solutions to replace conventional pesticides, cannabis companies and their cultivators can embrace simple, preventative measures to minimize outbreaks of bio-contaminants. This includes controlling humidity at the grow site, plant spacing, adequate air circulation, and implementing a strict chain of custody throughout the supply chain. Successful prevention mitigates the temptation to turn to potentially toxic pesticides to eradicate contaminants.

While federal legalization looms, it likely won’t happen this year. Therefore, state regulatory agencies should continue to be prepared with comprehensive outreach plans to communicate their pesticide and testing regulations to cultivators and their companies, ensuring that industry participants are fully informed. Planning and communication also sets the stage for the industry to have tried and true standards already in place by the time federal legalization does come to fruition.

The good news is the cannabis industry has the potential to lead a paradigm shift towards a safer agricultural sector as a whole. In years past, the amount of information shared between cannabis and other agricultural industries was limited, cutting cannabis cultivators off from reliable best practices for cultivation and crop management. However, this is changing quickly. Cannabis is also pushing the envelope towards more sustainable practices, with more cultivation sites moving indoors and into greenhouses, complete with LED lighting and additional sustainable practices. Cannabis cultivators are becoming more cutting-edge and setting an example for the broader agricultural community. The industry should continue these forward-thinking approaches by embracing pesticide-free solutions on a broad, scalable level.

Carlos Perea is the CEO and Co-founder of Terra Vera, an agricultural technology company offering innovative solutions to replace conventional pesticides and increase product safety and consumer confidence within the agriculture industry. Carlos is a serial entrepreneur with a focus on the intersection of technology and social impact. Prior to founding Terra Vera, he formed MIOX Corporation, a technology company that treats water in a variety of applications and is distributed in over 30 countries. He is active as an advisor and board member with several early stage companies and social enterprises including YPO, where is he an active board member. Carlos has an MBA from the Stanford Graduate School of Business, and an BS in Mechanical Engineering from the University of New Mexico.

Carlos Perea is the CEO and Co-founder of Terra Vera, an agricultural technology company offering innovative solutions to replace conventional pesticides and increase product safety and consumer confidence within the agriculture industry. Carlos is a serial entrepreneur with a focus on the intersection of technology and social impact. Prior to founding Terra Vera, he formed MIOX Corporation, a technology company that treats water in a variety of applications and is distributed in over 30 countries. He is active as an advisor and board member with several early stage companies and social enterprises including YPO, where is he an active board member. Carlos has an MBA from the Stanford Graduate School of Business, and an BS in Mechanical Engineering from the University of New Mexico.

Member Blog: Strategies to Reduce Indoor Cultivation Facility Energy Costs

by Jason Magnuson of Mintropy

Indoor cannabis cultivation facilities are complex environments, where a large number of variables interact to create an ideal ecosystem to grow cannabis. The upside of an indoor facility is it allows a year-long growing climate, optimized for each stage of the plant grow cycle. The downside, however, is creating this ideal climate is very energy-intensive.

The total energy costs for indoor cannabis grow operations typically vary between 20%-50% of total operating costs (approximately 120-150 kWh/sq.ft). In comparison, energy use in a typical commercial building environment is approximately 25 kWh/sq. ft. As indoor cultivation facilities increase, they can be a source of strain on electrical grids. A recent study showed indoor cannabis cultivation alone accounted for 4% of the energy grid usage in Denver. (IEEE, 2020)

With that context, any areas we can identify to improve energy efficiencies without introducing a negative impact to the grow environment can have enormous bottom-line impacts for cultivation owners and society at large.

In this article, we are going to be examining two ways we can optimize HVACD systems to improve energy efficiency. When HVACD systems are designed for grow facilities, the primary variables we are looking to influence are the following psychrometric properties: temperature (either wet or dry bulb) and relative humidity. Mechanical engineers will often refer to an information-packed graph called a psychrometric chart shown below.

This chart helps to visualize the relationships different properties of air like temperature, humidity (relative and absolute) and dew points along the saturation curve have with each other. This is useful to analyze, as these are direct inputs to a scientific measure often favored by growers called Vapor Pressure Deficit (VPD).

Vapor Pressure Deficit, simply described, compares these variables to determine how much additional room for water vapor there is in the air. This is important as it determines how well cannabis plants can transpire. Controlling transpiration rates help to aid in healthy, robust growth through the plant life cycle. Growers tend to want lower VPD, and thus lower transpiration, early in plant maturity, and increase to higher VPDs, and thus high transpiration, at the flowering stage before harvesting.

So we know a successful indoor cultivation facility HVAC system will need to control temperature and humidity to ensure the desired VPD values. How can we do that efficiently?

Stand-Alone Dehumidifiers Are Inefficient

A cannabis plant can transpire up to 99% of the water absorbed through its roots. Due to this, we often tell people that designing an Indoor Cultivation Facility is like designing a Data Center with a swimming pool inside. Because of the increased humidity introduced from plant transpiration, we must pay special attention to dehumidification strategies within the grow space. Humid air requires treating significant latent loads in the grow space, requiring additional energy to remove moisture from the airstream. This is one reason HVACD systems can consume up to 50% of the energy budget in a cultivation facility. As previously mentioned, higher humidity levels will lower the VPD in the room, preventing a plant from transpiring effectively to continue healthy growth. To combat this, sometimes stand-alone dehumidifiers are added into the grow room.

While these units can do the job of removing moisture from the room, it is a very energy-intensive process. One of the issues with stand-alone dehumidifiers is that they reject heat back into the grow room, thereby adding additional cooling load onto the main HVAC equipment.

Integral Hot Gas Bypass System

An air handling unit, sometimes called an air handler or AHU, is a piece of equipment that is used to condition and circulate air as a component of a heating, ventilating, and air conditioning system.

The air handler is usually a large metal box that contains a blower, heating and cooling elements, filter chambers, sound attenuators, and dampers. It then connects to ductwork that distributes the conditioned air throughout the space before returning it back to the AHU.

Of particular interest are the units cooling coil and reheat coil. These two components are namely responsible for controlling VPD levels in our grow space. In an Integral Hot Gas Reheat AHU, the cooling coil serves as a dehumidifier, by cooling the air thereby reducing its moisture/latent load (we highly recommend capturing this water for treatment and reuse: read more here). The hot gas reheat capability utilizes heat from grow space and compressor heat to reheat the air before returning to the grow space (without using additional heating energy).

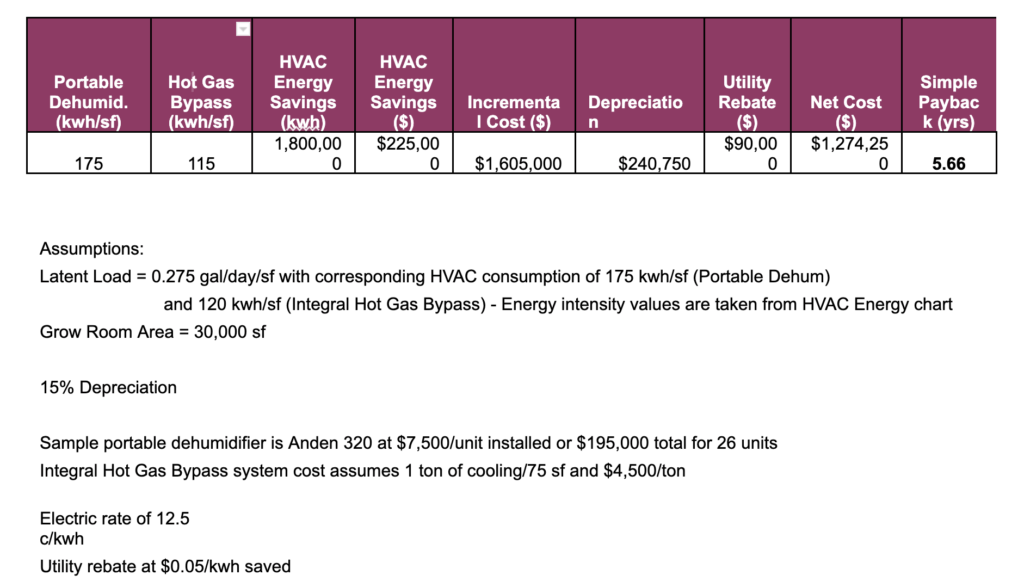

While this may seem like a minor design change, it results in a considerable reduction in energy. As the chart below illustrates, leveraging the Integral Hot Gas Bypass AHU units can result in a 30-35% reduction in HVACD energy when compared with other dehumidification systems. Additional automation capabilities built-into these systems will ensure that the grow room will remain tightly controlled within the desired state points of your grow room to optimize VPD.

This reduction in energy quickly adds up to reduced utility bills. Despite marginally higher upfront costs as compared to standard HVAC equipment coupled with standalone dehumidifiers, this option results in a lower 5-year system cost than common HVACD systems installed in cultivation facilities, and these savings will only increase over time.

Maintaining Consistent VPD, but at higher Temperature / Humidity Ranges

The second energy-saving measure we would like to discuss goes back to the earlier discussion of VPD. Recall the equation for VPD is

V P sat – V P air = VPD

This is important, as it provides growers the flexibility to fall within desired VPD ranges, but at higher temperature and humidity ranges than typically used. Many growers target maximum temperatures around 70-75F and limit relative humidity to a maximum of 50 percent, but by allowing slightly higher maximum room temperatures of 75-80F, with corresponding relative humidity increases, we can create identical VPDs. The cost-benefit of this small adjustment is considerable. The HVAC system (including cooling and dehumidification) can be sized at roughly 20-30% smaller capacity, reducing the grower’s up-front equipment costs. In addition, the system’s energy consumption and costs during operations will be significantly lower, to the tune of 30-40%. In a theoretical 30,000 square foot facility, this could result in a $1,300,000 savings in the first 5 years.

Jason Magnuson is the Director of Business Development at mintropy. Mintropy is an MEP (Mechanical, Electrical, Plumbing) Engineering Design firm, with a focus on Indoor Cultivation Facility and Dispensary design. At mintropy, we strive to minimize entropy (minimize disorder) in building systems, by creating innovative and efficient designs to meet our client’s needs. For assistance in your cultivation facility, be it auditing/upgrading existing systems or designing new, reach out to us today.

Jason Magnuson is the Director of Business Development at mintropy. Mintropy is an MEP (Mechanical, Electrical, Plumbing) Engineering Design firm, with a focus on Indoor Cultivation Facility and Dispensary design. At mintropy, we strive to minimize entropy (minimize disorder) in building systems, by creating innovative and efficient designs to meet our client’s needs. For assistance in your cultivation facility, be it auditing/upgrading existing systems or designing new, reach out to us today.

by NCIA’s

by NCIA’s

Carlos Perea is the CEO and Co-founder of

Carlos Perea is the CEO and Co-founder of