Committee Blog: VPD Topics for Cannabis Cultivation and Opportunities to Reduce Facility Energy Costs

by NCIA’s Facilities Design Committee

by NCIA’s Facilities Design Committee

Indoor cannabis cultivation facilities are complex environments, where a large number of variables interact to create an ideal ecosystem to grow cannabis. The upside of an indoor facility is it allows a year-long growing climate, optimized for each stage of the plant grow cycle. The downside, however, is creating this ideal climate is very energy-intensive.

There are three (3) main types of precision cooling equipment offered in the cultivation space. Those are Air Cooled DX, Water Cooled DX, and Chilled Water Units. DX stands for direct expansion systems. The immediate and most noteworthy difference between these systems is that DX units cool air using refrigerant, and Chilled Water units cool air utilizing chilled water. A DX unit uses refrigerant-based cooling and cools indoor air using a condensed refrigerant liquid. Typically, the decision regarding which cooling source is better for a cultivation facility is usually driven by the size of the cooling plant as well as other unique site conditions. Selecting the right HVAC system for your cultivation facility can be a challenging process driven by many factors, however this is beyond the topic of discussion for this article, it should be noted that the following analysis assumes an Air Cooled DX based system.

The total energy costs for indoor cannabis grow operations typically vary between 25%-50% of total operating costs (or approximately 150-200 kWh/sq.ft). In comparison, energy use in a typical commercial building environment is approximately 25 kWh/sq. ft. As indoor cultivation facilities increase, they can be a source of strain on electrical grids. A recent study showed indoor cannabis cultivation alone accounted for 4% of the energy grid usage in Denver. (IEEE, 2020)

With that context, any areas we can identify to improve energy efficiencies without introducing a negative impact to the grow environment can have enormous bottom-line impacts for cultivation owners and society at large.

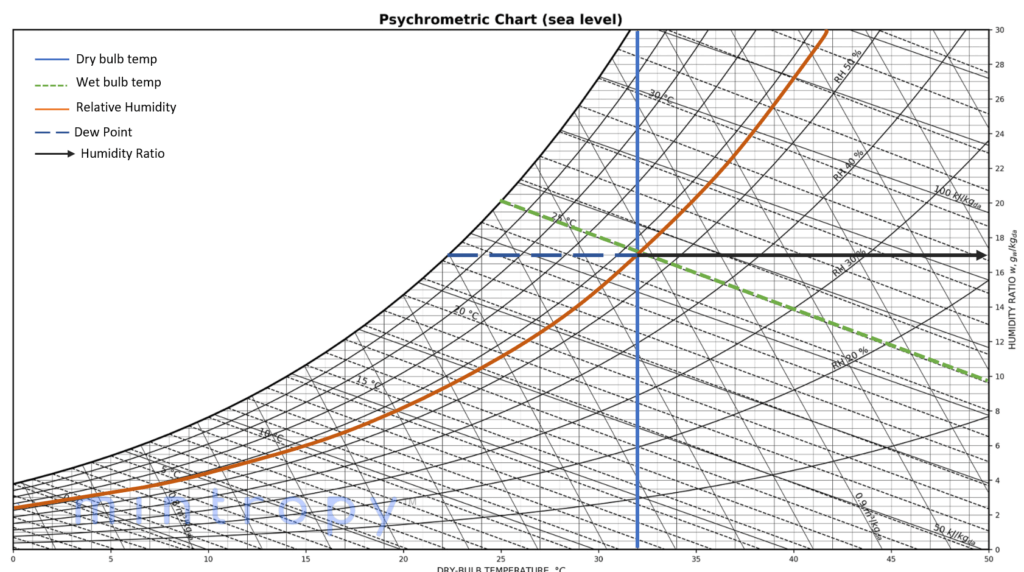

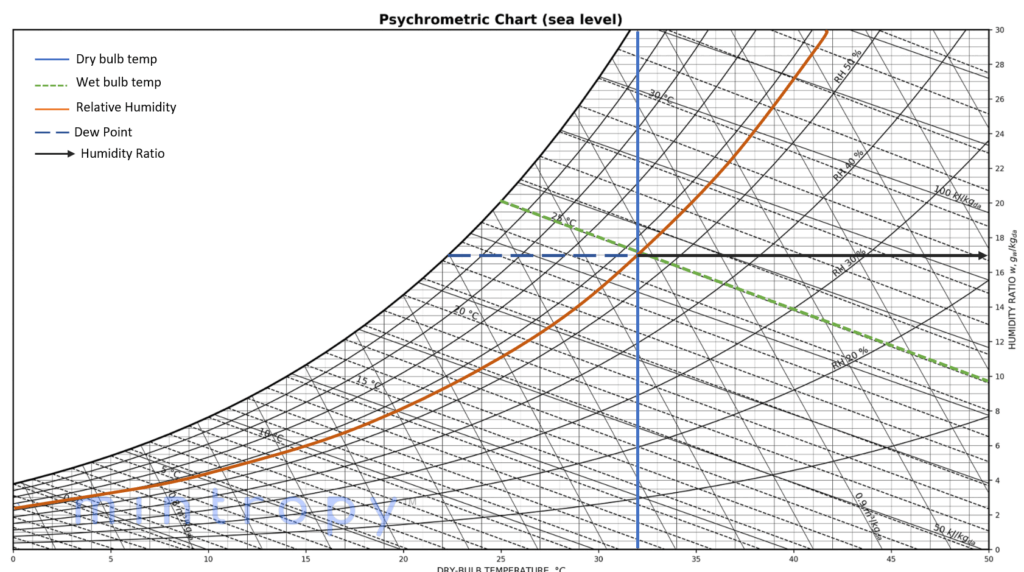

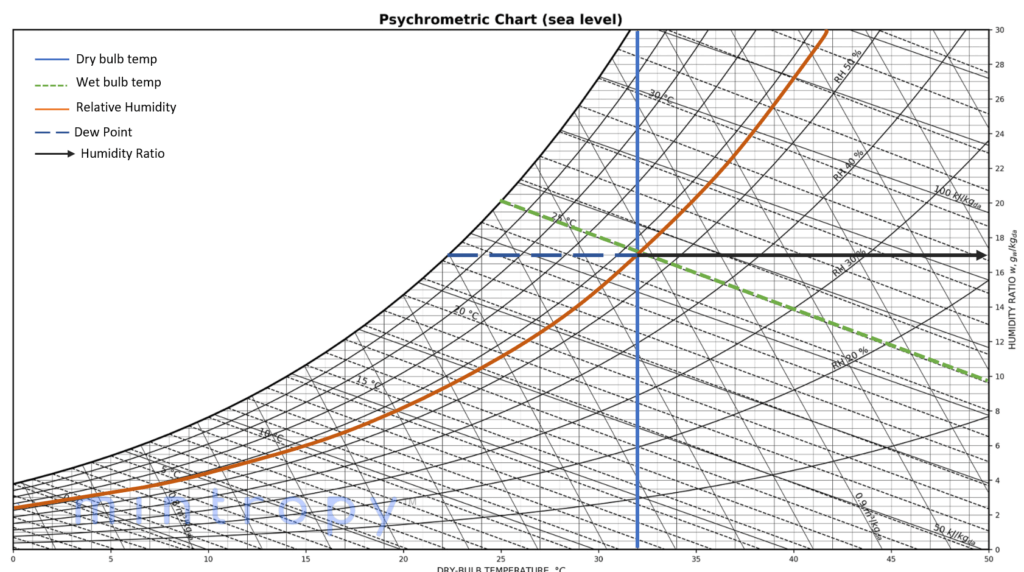

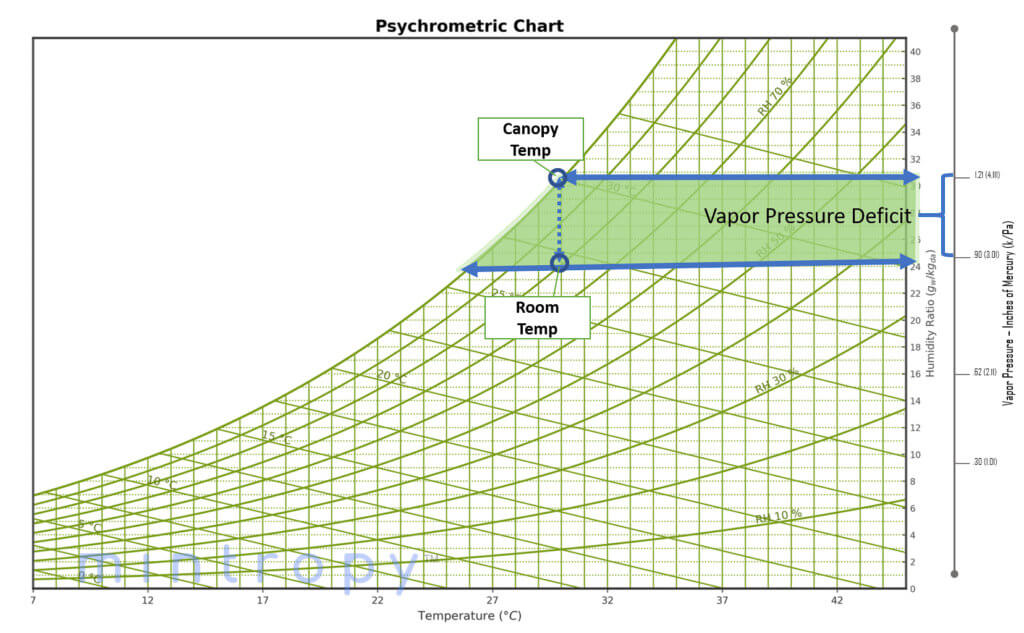

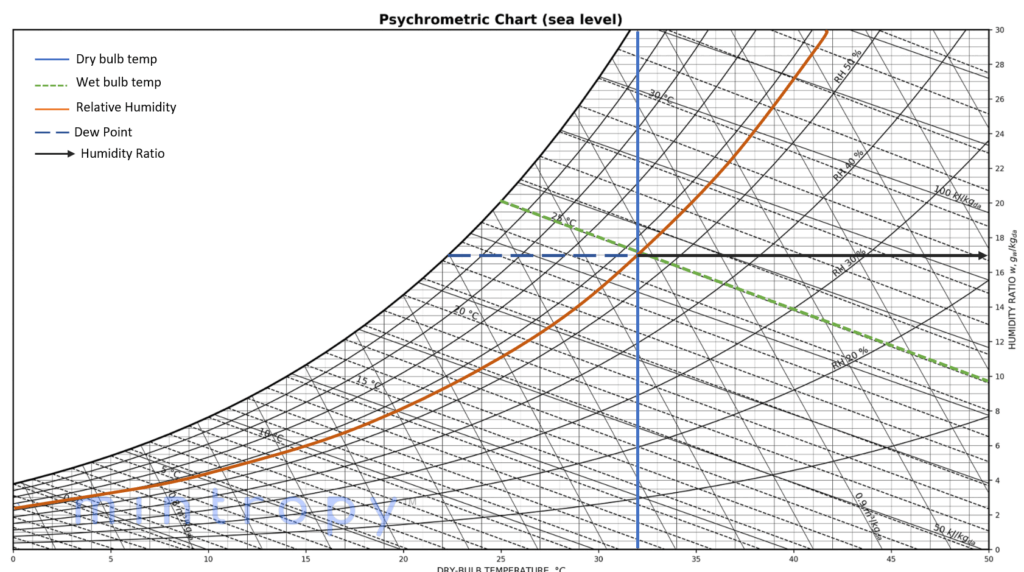

In this article, we are going to be examining two ways we can optimize HVACD systems to improve energy efficiency. When HVACD systems are designed for grow facilities, the primary variables we are looking to influence are the following psychrometric properties: temperature (either wet or dry bulb) and relative humidity. Mechanical engineers will often refer to an information-packed graph called a psychrometric chart shown below.

This chart helps to visualize the relationships different properties of air like temperature, humidity (relative and absolute) and dew points along the saturation curve have with each other. This is useful to analyze, as these are direct inputs to a scientific measure often favored by growers called Vapor Pressure Deficit (VPD).

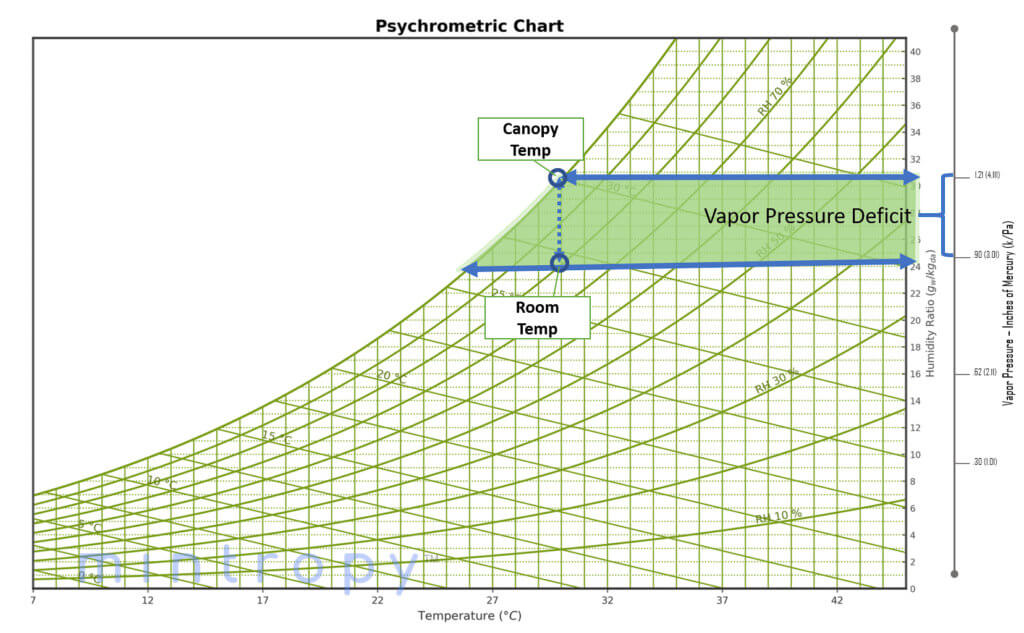

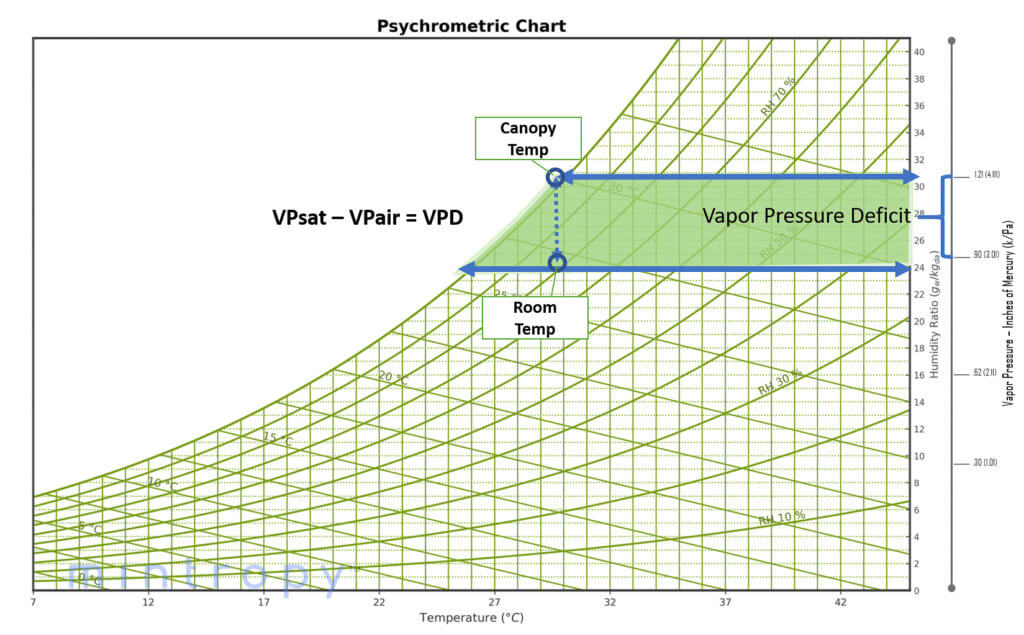

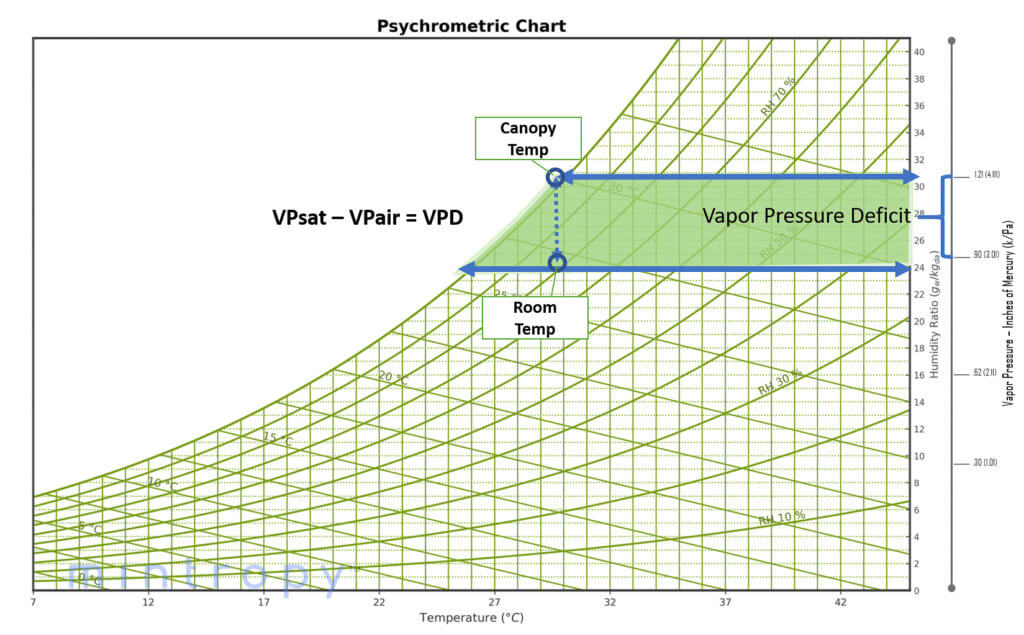

Vapor Pressure Deficit, simply described, compares these variables to determine how much additional room for water vapor there is in the air. This is important as it determines how readily cannabis plants can transpire. Controlling transpiration rates help to aid in healthy, robust growth through the plant life cycle. Growers tend to want lower VPD, and thus lower transpiration, early in plant maturity, and increase to higher VPDs, and thus high transpiration, at the flowering stage before harvesting.

So we know a successful indoor cultivation facility HVAC system will need to control temperature and humidity to ensure the desired VPD values. How can we do that efficiently?

Stand-Alone Dehumidifiers Are Inefficient

A cannabis plant can transpire up to 99% of the water absorbed through its roots. Due to this, we often tell people that designing an indoor cultivation facility is like designing a data center with a swimming pool inside. Because of the increased humidity introduced from plant transpiration, we must pay special attention to dehumidification strategies within the grow space. Humid air requires treating significant latent loads in the grow space, requiring additional energy to remove moisture from the airstream. This is one reason HVACD systems can consume up to 50% of the energy budget in a cultivation facility. As previously mentioned, higher humidity levels will lower the VPD in the room, preventing a plant from transpiring effectively to continue healthy growth. To combat this, sometimes stand-alone dehumidifiers are added into the grow room.

While these units can do the job of removing moisture from the room, it is a very energy-intensive process. One of the issues with stand-alone dehumidifiers is that they reject heat back into the grow room, thereby adding additional cooling load onto the main HVAC equipment.

Integral Hot Gas Reheat System

An air handling unit, sometimes called an air handler or AHU, is a piece of equipment that is used to condition and circulate air as a component of a heating, ventilating, and air conditioning system.

The air handler is usually a large metal box that contains a blower, heating and cooling elements, filter chambers, sound attenuators, and dampers. It then connects to ductwork that distributes the conditioned air throughout the space before returning it back to the AHU.

Of particular interest are the units cooling coil and reheat coil. These two components are namely responsible for controlling VPD levels in our grow space. In an AHU equipped with Integral Hot Gas Reheat, the cooling coil serves as a dehumidifier, by cooling the air thereby reducing its moisture/latent load (we recommend considering capturing this water for treatment and reuse: read more here). The hot gas reheat capability utilizes heat from grow space and compressor heat to reheat the air before returning to the grow space (without using additional heating energy).

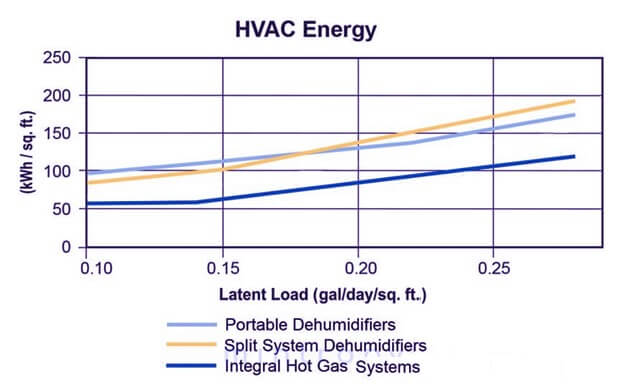

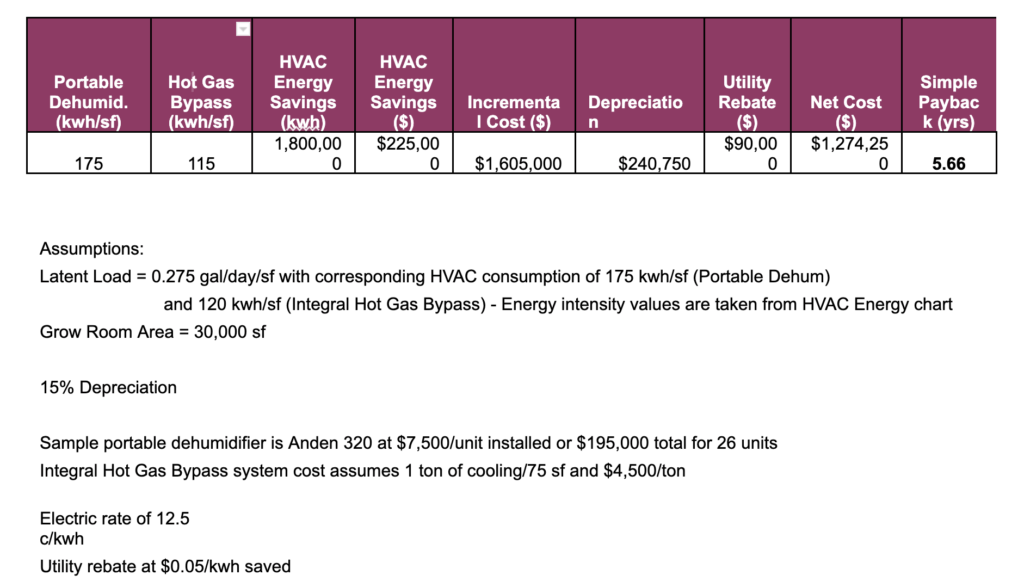

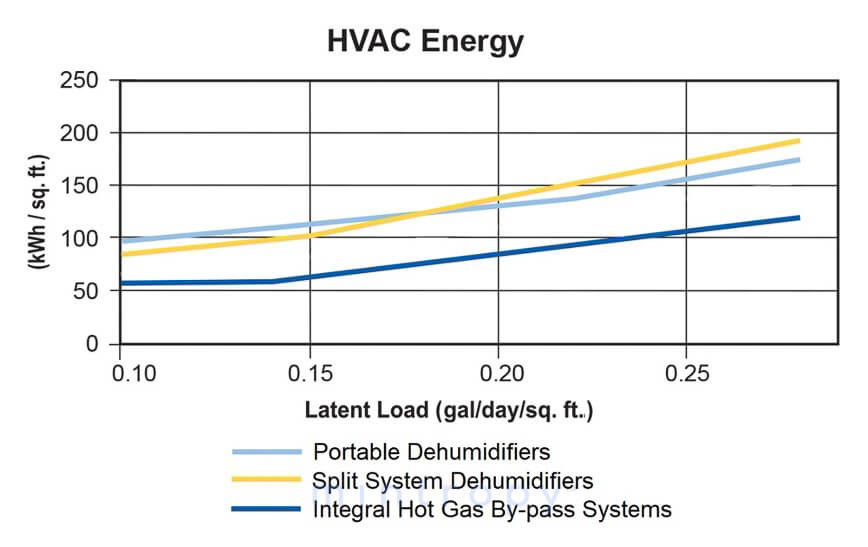

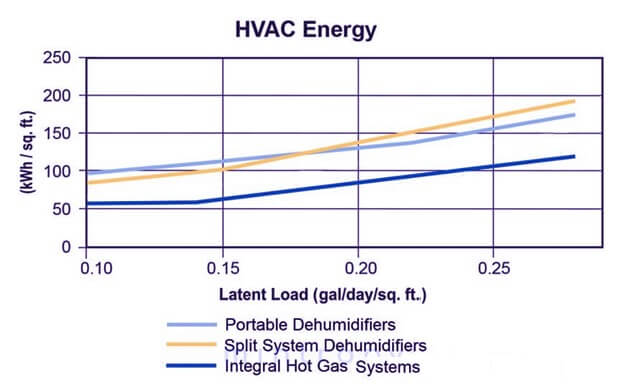

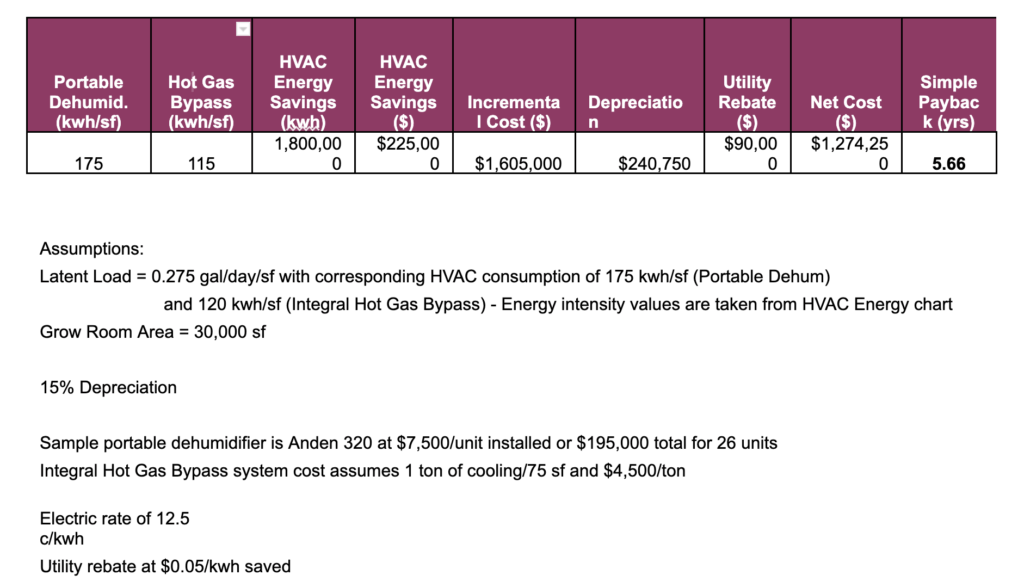

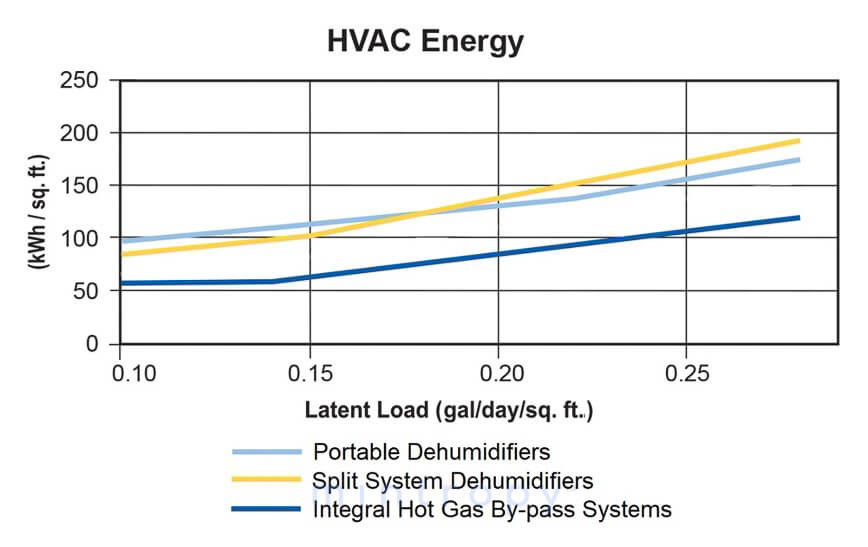

While this may seem like a minor design change, it results in a considerable reduction in energy. As the chart below illustrates, leveraging Integral Hot Gas Reheat units can result in a 30-35% reduction in HVACD energy when compared with other dehumidification systems. Additional automation capabilities built-into these systems will ensure that the grow room will remain tightly controlled within the desired state points of your grow room to optimize VPD.

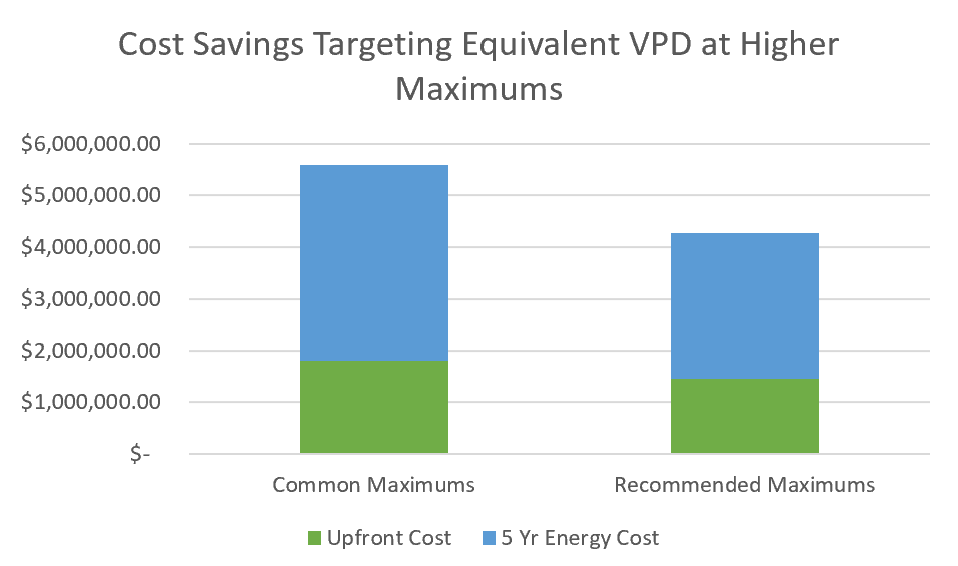

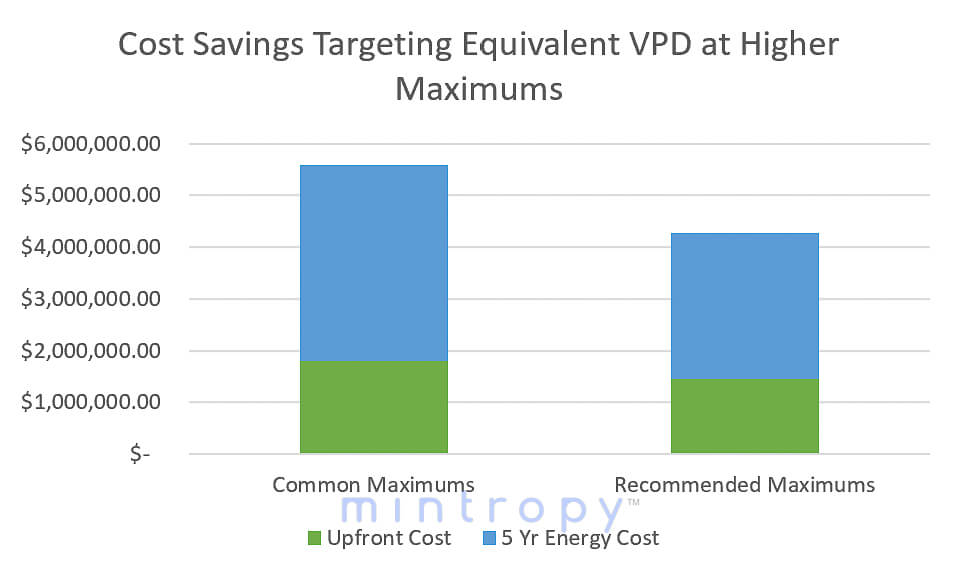

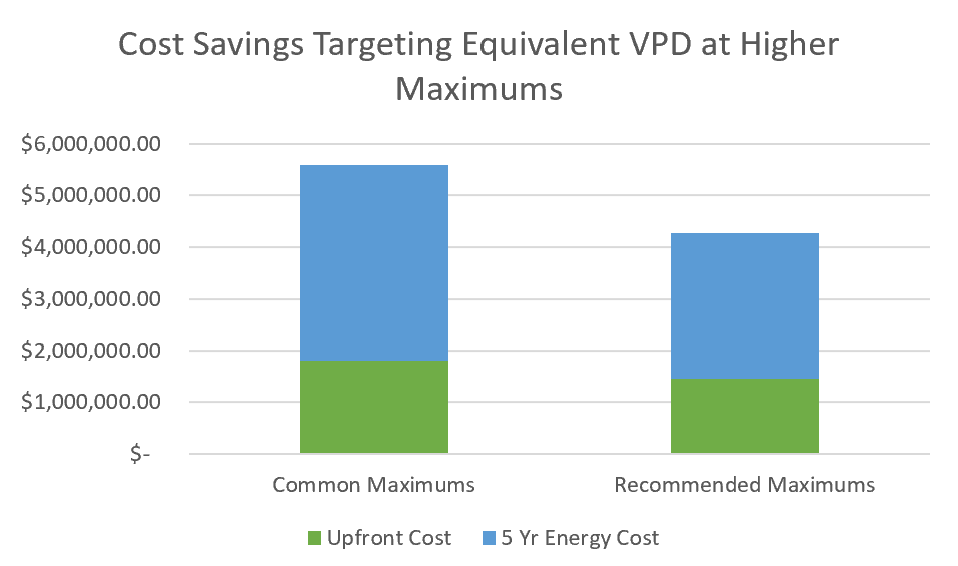

This reduction in energy quickly adds up to reduced utility bills. Despite marginally higher upfront costs as compared to standard HVAC equipment coupled with standalone dehumidifiers, this option results in a lower 5-year system cost than common HVACD systems installed in cultivation facilities, and these savings will only increase over time.

Maintaining Consistent VPD, but at higher Temperature / Humidity Ranges

The second energy-saving measure we would like to discuss goes back to the earlier discussion of VPD. Recall the equation for VPD is

V P sat – V P air = VPD

This is important, as it provides growers the flexibility to fall within desired VPD ranges, but at higher temperature and humidity ranges than typically used. Many growers target grow room setpoint temperatures around 72-75F and limit relative humidity to a maximum of 50 percent, but by allowing slightly higher room setpoint temperatures of 76-82F, with corresponding relative humidity increases, we can create identical VPDs at higher setpoint temperatures. The cost-benefit of this small adjustment is considerable. The HVAC system (including cooling and dehumidification) can be sized at roughly 20-30% smaller capacity, reducing the owner’s up-front equipment costs. In addition, the system’s energy consumption and costs during operations will be significantly lower, to the tune of 30-40%. In a theoretical 30,000 square foot facility, this could result in $1,125,000 savings in the first 5 years.

The case for a hybrid greenhouse, using VPD controls

Another way of growing instead of full indoor, is a highly efficient, sealed greenhouse. It is designed to maximize sunlight inside the growing environment, meaning energy used for lighting is dramatically reduced. And because it is sealed, energy-efficiency is maximized, as leakage is kept to a minimum. In order to make this work, these greenhouses need to be hybrid (using insulated walls and glazing) and the orientation and design play a bigger role.

In this hybrid greenhouse environment, the growing space typically heats up as soon as the sun comes out, no matter the outside temperature. Cooling in this instance would increase the power usage vs. increasing the humidity to keep the VPD level in the same range. When the sun goes down, the opposite happens. The grow environment starts to cool and it would be expensive to try and keep the temperature up.

In order to achieve VPD control, the control system needs to be able to variably adjust temperature and humidity, based on inputs like weather forecast, time of the day, day of the year, etc. Being able to control the grow environment by VPD level will significantly reduce the energy consumption for your HVACD system.

Committee Blog: Everything You Wanted to Know About Cannabis Facilities But Were Afraid to Ask Field Guide – Part 2 – Extraction Facilities

by members of NCIA’s Facilities Design Committee

by members of NCIA’s Facilities Design Committee

Jacques Santucci, Brian Anderson, David Vaillencourt, and David Dixon

Continuing our five-part series on the behind-the-scenes workings of the legal cannabis industry. This series focuses on all of the inner dealings and industry advice from established professionals to craft this unlimited How-to-Guide to assist you in setting up your own facility. These articles cover cultivation, extraction, infused products, and retail facilities as well as support activities. In general, remember to be compliant with all local rules and regulations and contact a licensed contractor and industry expert.

Part Two, Extraction: Top Things to Consider When Planning Your Cannabis Extraction Operation

The extraction environment is akin to an industrial process and should be approached away from a safety and chemical handling standpoint. Here are some general considerations as you begin to plan your extraction operation that we often see assumed or overlooked resulting in major unanticipated barriers that significantly impact decision costs and timelines. Always remember to be compliant with all local rules and regulations.

Interior Building Materials

The walls and floors should be designed to be easily cleanable. In areas with solvent use, should have floors and walls made with the material, and ultimately the method for effective and ease of cleaning such FRP (Fiberglas Reinforced Panels).

Facility Specifications

There are many established standards from organizations like the NFPA and ICC-IFC which are commonly cited and required by Fire Marshalls with appropriate fire engineering controls, room interlocks, etc. Knowing which classifications are required based on the room type has a major impact on facility specifications (e.g. C1D1, C1D2, etc.) and the ultimate design. This requires knowing which solvents you will be using (and equally important, solvents you will not be using) as well as identifying all of the activities you will be doing in your extraction/processing facility (winterization, purification, bulk or final product packaging, and more) and whether the rooms will be wet and dry (how will you be cleaning these rooms?). How you answer those questions will help you and your team select the appropriate room materials and overall design.

Electrical Power Ideal Recommendations

Evaluate your utility power infrastructure, including street transformers and available power to your site when designing your facility. The power demand for a cannabis facility is significant and grid limitations can destroy or significantly delay the ability for a business to operate.

Losing power due to weather or events outside of your control are another major risk. When considering alternative power generation, consider a generator with auto-transfer switching and the appropriate fuel type, depending on location and local weather. Contact a local licensed professional. A generator can be an invaluable insurance policy as even a short duration power outage can destroy an entire crop and any products that must be maintained at critical temperatures.

Equipment Rooms and Maintenance Rooms

Appropriate space for equipment and dedicated rooms for maintenance is commonly needed. These all come with different combustion air requirements, venting requirements, air exchange rates, vacuum lines, and more. You may consider a room for spare parts and tools.

Appropriate Storage Area: Biomass, Volatiles, Raw Ingredients, and More

Separation of raw materials with appropriate and dedicated storage areas is needed for the various types of raw ingredients and materials utilized within a cannabis facility. Volatile solvents require extremely specific storage requirements, which will become part of your Chemical Hygiene Plan once you are operational. Refer to your local Fire Marshall for code considerations and from code organizations like the ICC and NFPA.

Cleaning and sanitation agents should be segregated from materials that are utilized in final product formulations (e.i food ingredients, oils, etc.) and raw materials ahead of the design is critical to ensure appropriate storage requirements are met whether indoor or outdoor. Biomass storage can vary based on whether wet or dry and often require controlled temperature and humidity. Finally, do not forget the dedicated space needed for finished good inventory.

Electrostatic Discharge (ESD) Safety

Do you know that shock you get when you are in your car in the winter or flipping on a light switch? Innocent in everyday life, but potentially lethal in an environment such as extraction rooms where highly flammable solvents could be present. Consider rated and non-rated clothing and other personal protection measures.

Food Grade Oil Considerations and Inspections

Extracted oils that will be used downstream in edibles and beverages are akin to ingredients that require Food Safety endorsements such as cGMP.

Equipment Ratings

Before selecting equipment for use, evaluation criteria should be established based on your business needs and compliance. Some authorities having jurisdiction require extraction equipment to come with stamps, certifications, or endorsements from organizations such as ASME, UL, and NFPA as relevant to ensure equipment safety and fit for use.

Room Environmental Controls

Grinding rooms often need separate dedicated ventilation and filtration to be checked against grinding method/equipment and concentration of particulate (typically measured in parts per million (ppm) in the air. Dust collection systems for grinding equipment are effective ways to keep dust levels at manageable levels, reducing the need for time consuming cleaning procedures. Extraction and final product rooms may require additional ventilation considerations and monitoring sensors depending on the extraction method or final product type. Example: Solvents will require sensors and air exchanges located near the ground level since most solvent fumes tend to be heavier than air.

HVACD Management

Designing your facility involves HVACD (Heating, Ventilation, Air Conditioning, and Dehumidification) management that considers airflow controls areas, airflow, and fire protection within control areas. Rooms may require positive and negative pressures with calibrated pressure indicators. You should aim at having a leveled constant environment.

Safety and Injury Handling

Facilities need to have sufficient accessible First Aid and Burn Kits on site. Safety and Emergency Showers are often determined by code and the type of extraction solvent in use at the locations. Eye wash stations may also be required.

Spill and Solvent Safety

In areas where solvents are or may be used, you will need to have barrier/spill kits specific to the solvents and extraction materials on hand. This barrier can be built in or hand delivered per emergency. Solvent storage locations, depending on the type of solvent and hazardous rating.

Having one or two dedicated people to run point on spills can be part of a comprehensive spill procedure that would include evacuation of the area, assessment of the spill and of the clean up technique, disposal method, etc. There are many materials that are not compatible or properties that make them volatile under certain circumstances so having dedicated people to evaluate the situation will save you time, money, and any possible mishaps.

Solvent Storage

Indoor and outdoor solvent storage are dictated by NFPA, ICC-IFC, and local regulations. Storage types and limits are essential to check before buying or building a facility. Fire professionals base these limits on several factors of flammability including class and volatility. You may also need to adhere to SARA Type III reporting depending on the solvent and storage amounts. Do not forget about solvent tank types, whether they need to be mounted or chained to walls, security access controls, and SDS requirements.

Solvent Enclosure

C1D1, C1D2 is needed for solvent use. The actual type of solvents (e.g. CO2, Ethanol, etc.), and volume of solvent will dictate the different requirements for enclosures. This section pertains to areas in which the solvent would be transferred, mixed, extracted, recovered, etc. The type of enclosure is dependent on the type and class of solvent. Most enclosures will have volume limits, containment, vapor detector, electrical and ventilation requirements.

Emergency Ventilation

Ensure wall switch and fast ventilation, automated ventilation when sensors are activated during spill of contaminate.Sensors to be located where appropriate for the substance in use. Coordinated with the fire marshall to meet local requirements through design with architect and mechanical teams.

Employee Access Control

Limiting door access, proper security labeling, and key sets for employees need to be part of your overall security plan. LThe idea is to prevent unauthorized personnel from accessing the extraction space compliant with the local regulatory body.

Equipment Regulatory Listing

There are requirements such as UL certifications/marks which are dependent on the actual device and intended use. Always contact your local code enforcement office and a licensed contractor.

Check Out These Related Articles for More Top Things to Consider When Planning:

Part 1 – Cannabis Cultivation Facilities

Part 2 – Cannabis Extraction Facilities

Part 3 – Cannabis Food Production Facilities

Part 4 –Cannabis Retail & Dispensary Facilities

Part 5 – Cannabis Facility Support Areas

Member Blog: Strategies to Reduce Indoor Cultivation Facility Energy Costs

by Jason Magnuson of Mintropy

Indoor cannabis cultivation facilities are complex environments, where a large number of variables interact to create an ideal ecosystem to grow cannabis. The upside of an indoor facility is it allows a year-long growing climate, optimized for each stage of the plant grow cycle. The downside, however, is creating this ideal climate is very energy-intensive.

The total energy costs for indoor cannabis grow operations typically vary between 20%-50% of total operating costs (approximately 120-150 kWh/sq.ft). In comparison, energy use in a typical commercial building environment is approximately 25 kWh/sq. ft. As indoor cultivation facilities increase, they can be a source of strain on electrical grids. A recent study showed indoor cannabis cultivation alone accounted for 4% of the energy grid usage in Denver. (IEEE, 2020)

With that context, any areas we can identify to improve energy efficiencies without introducing a negative impact to the grow environment can have enormous bottom-line impacts for cultivation owners and society at large.

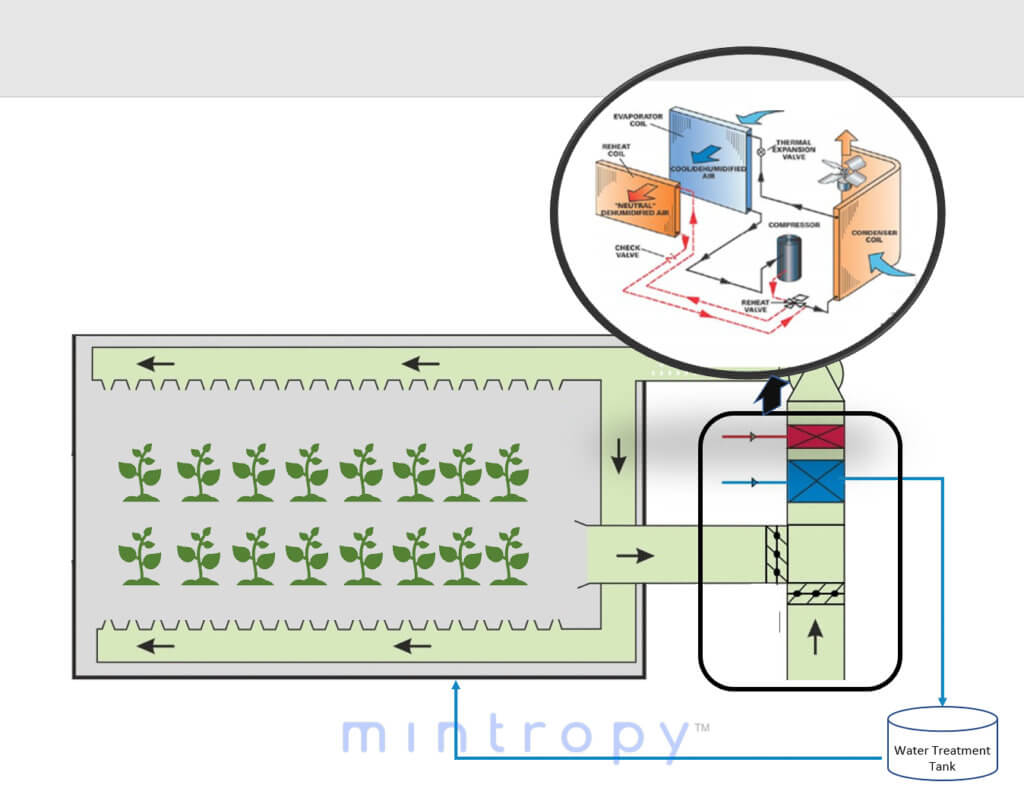

In this article, we are going to be examining two ways we can optimize HVACD systems to improve energy efficiency. When HVACD systems are designed for grow facilities, the primary variables we are looking to influence are the following psychrometric properties: temperature (either wet or dry bulb) and relative humidity. Mechanical engineers will often refer to an information-packed graph called a psychrometric chart shown below.

This chart helps to visualize the relationships different properties of air like temperature, humidity (relative and absolute) and dew points along the saturation curve have with each other. This is useful to analyze, as these are direct inputs to a scientific measure often favored by growers called Vapor Pressure Deficit (VPD).

Vapor Pressure Deficit, simply described, compares these variables to determine how much additional room for water vapor there is in the air. This is important as it determines how well cannabis plants can transpire. Controlling transpiration rates help to aid in healthy, robust growth through the plant life cycle. Growers tend to want lower VPD, and thus lower transpiration, early in plant maturity, and increase to higher VPDs, and thus high transpiration, at the flowering stage before harvesting.

So we know a successful indoor cultivation facility HVAC system will need to control temperature and humidity to ensure the desired VPD values. How can we do that efficiently?

Stand-Alone Dehumidifiers Are Inefficient

A cannabis plant can transpire up to 99% of the water absorbed through its roots. Due to this, we often tell people that designing an Indoor Cultivation Facility is like designing a Data Center with a swimming pool inside. Because of the increased humidity introduced from plant transpiration, we must pay special attention to dehumidification strategies within the grow space. Humid air requires treating significant latent loads in the grow space, requiring additional energy to remove moisture from the airstream. This is one reason HVACD systems can consume up to 50% of the energy budget in a cultivation facility. As previously mentioned, higher humidity levels will lower the VPD in the room, preventing a plant from transpiring effectively to continue healthy growth. To combat this, sometimes stand-alone dehumidifiers are added into the grow room.

While these units can do the job of removing moisture from the room, it is a very energy-intensive process. One of the issues with stand-alone dehumidifiers is that they reject heat back into the grow room, thereby adding additional cooling load onto the main HVAC equipment.

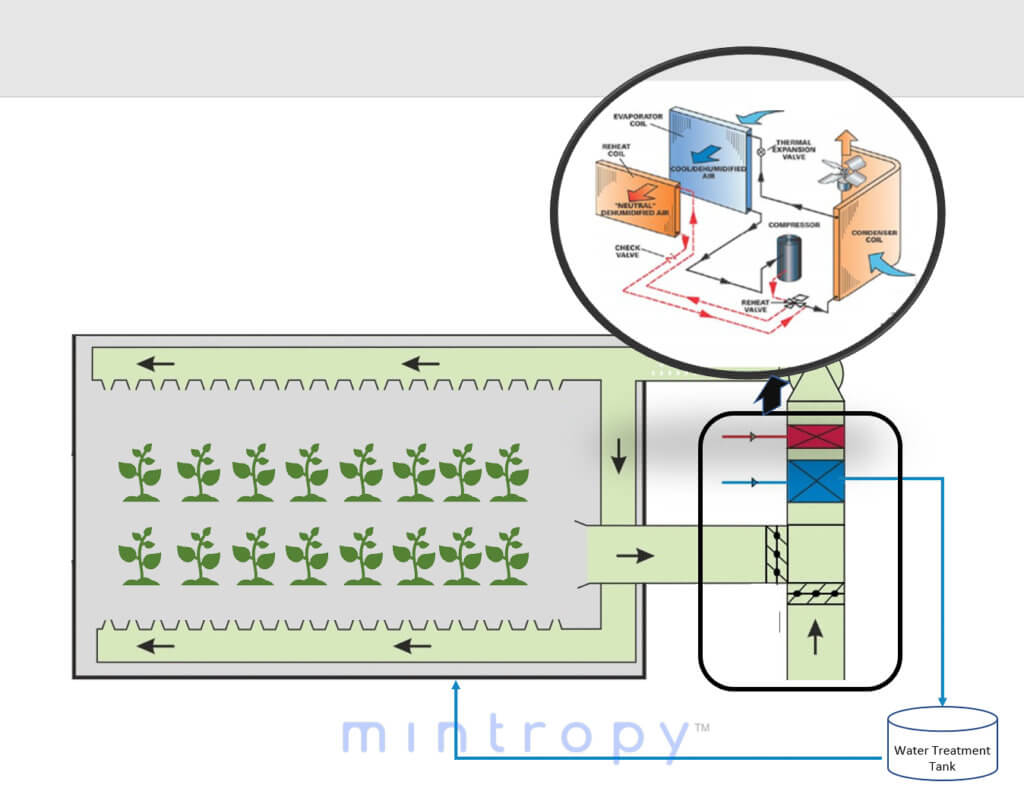

Integral Hot Gas Bypass System

An air handling unit, sometimes called an air handler or AHU, is a piece of equipment that is used to condition and circulate air as a component of a heating, ventilating, and air conditioning system.

The air handler is usually a large metal box that contains a blower, heating and cooling elements, filter chambers, sound attenuators, and dampers. It then connects to ductwork that distributes the conditioned air throughout the space before returning it back to the AHU.

Of particular interest are the units cooling coil and reheat coil. These two components are namely responsible for controlling VPD levels in our grow space. In an Integral Hot Gas Reheat AHU, the cooling coil serves as a dehumidifier, by cooling the air thereby reducing its moisture/latent load (we highly recommend capturing this water for treatment and reuse: read more here). The hot gas reheat capability utilizes heat from grow space and compressor heat to reheat the air before returning to the grow space (without using additional heating energy).

While this may seem like a minor design change, it results in a considerable reduction in energy. As the chart below illustrates, leveraging the Integral Hot Gas Bypass AHU units can result in a 30-35% reduction in HVACD energy when compared with other dehumidification systems. Additional automation capabilities built-into these systems will ensure that the grow room will remain tightly controlled within the desired state points of your grow room to optimize VPD.

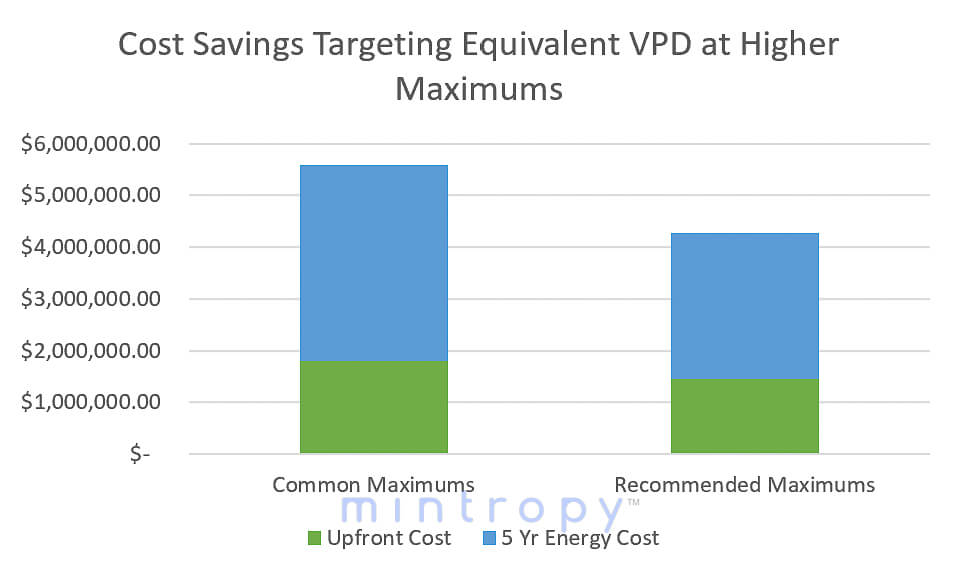

This reduction in energy quickly adds up to reduced utility bills. Despite marginally higher upfront costs as compared to standard HVAC equipment coupled with standalone dehumidifiers, this option results in a lower 5-year system cost than common HVACD systems installed in cultivation facilities, and these savings will only increase over time.

Maintaining Consistent VPD, but at higher Temperature / Humidity Ranges

The second energy-saving measure we would like to discuss goes back to the earlier discussion of VPD. Recall the equation for VPD is

V P sat – V P air = VPD

This is important, as it provides growers the flexibility to fall within desired VPD ranges, but at higher temperature and humidity ranges than typically used. Many growers target maximum temperatures around 70-75F and limit relative humidity to a maximum of 50 percent, but by allowing slightly higher maximum room temperatures of 75-80F, with corresponding relative humidity increases, we can create identical VPDs. The cost-benefit of this small adjustment is considerable. The HVAC system (including cooling and dehumidification) can be sized at roughly 20-30% smaller capacity, reducing the grower’s up-front equipment costs. In addition, the system’s energy consumption and costs during operations will be significantly lower, to the tune of 30-40%. In a theoretical 30,000 square foot facility, this could result in a $1,300,000 savings in the first 5 years.

Jason Magnuson is the Director of Business Development at mintropy. Mintropy is an MEP (Mechanical, Electrical, Plumbing) Engineering Design firm, with a focus on Indoor Cultivation Facility and Dispensary design. At mintropy, we strive to minimize entropy (minimize disorder) in building systems, by creating innovative and efficient designs to meet our client’s needs. For assistance in your cultivation facility, be it auditing/upgrading existing systems or designing new, reach out to us today.

Jason Magnuson is the Director of Business Development at mintropy. Mintropy is an MEP (Mechanical, Electrical, Plumbing) Engineering Design firm, with a focus on Indoor Cultivation Facility and Dispensary design. At mintropy, we strive to minimize entropy (minimize disorder) in building systems, by creating innovative and efficient designs to meet our client’s needs. For assistance in your cultivation facility, be it auditing/upgrading existing systems or designing new, reach out to us today.

Committee Blog: An Introduction to HVACD for Indoor Plant Environments – Why We Should Include a “D” for Dehumidification

by NCIA’s Facilities Design Committee

Transpiration and VPD are two fundamental components of plant vitality, and heating, ventilation, and air conditioning (HVAC) systems are one of the most critical considerations for an indoor cannabis cultivator. HVAC alone doesn’t tell the full story of environmental control for cultivation facilities. The term HVAC is typically used to refer to the cooling, heating, or ventilation systems in a building, and while it technically includes dehumidification in most forms, it does not directly highlight the significant dehumidification requirements necessary to maintain optimum plant health inside indoor cultivation spaces. In order to emphasize the importance of dehumidification in the mechanical equipment sizing and selection process, the controlled environment horticulture industry would benefit from moving toward the concept of heating, ventilation, air conditioning, and dehumidification (HVACD) as the common term for these systems.

“HVAC” Challenges

The term HVAC is typically used to reference conventional air conditioning and heating systems designed for temperature control to provide a comfortable environment for people. This is clearly demonstrated in the very design of these systems – for example, sensible heat ratios of commercial HVAC equipment are pretty high in order to meet the loads generated by people, lighting, and miscellaneous equipment found in offices. Plants grown in enclosed spaces have different needs than people do. Of particular interest is the large amount of dehumidification that needs to be performed on a daily basis to maintain an optimum vapor pressure deficit (VPD).

When you apply a standard HVAC system to indoor horticulture, the instant the sensible load is removed from the space (i.e. the lights turn off), the air conditioning unit reaches the lower deadband of the specified temperature set point and shuts off. In the process of bringing the temperature down, we have raised the relative humidity to the detriment of the plants. Further, despite being mostly sensible cooling machines, conventional HVAC systems provide most of the dehumidification capacity in an indoor cultivation space, and that capacity is now inactive during the dark period.

Traditionally, growers would install stand-alone, pocket dehumidifiers to handle the moisture removal requirements that the air conditioning units cannot meet. There are a handful of challenges with this approach that can negatively impact plant health when scaling into industrial-scale operations. Most standalone dehumidifiers dry the air with mechanical refrigeration and in the process add hot air into the room, which then needs to be cooled by additional cooling equipment to maintain temperature. Another challenge is the numerous condensate drains throughout the growing space that are high risk for clogging and quickly leading to pest and pathogen proliferation which are potential GMP and GFSI compliance risks. The separate cooling and dehumidification systems typically do not have communication and control amongst them and ultimately “fight” against each other for temperature and relative humidity setpoints. Additional pest vectors can come into play when the HVAC contractor enters the cultivation or curing space to make repairs on mechanical equipment that is mounted above plants. Above all, maintaining cleanliness in the space can be challenging with many mechanical units perched above a dynamic plant canopy.

Dehumidification, or removing humidity from a room that is filled with water vapor as a result of plant transpiration, is arguably the biggest environmental challenge in controlled environment horticulture. When you size an HVAC system for human comfort or server rooms, the primary focus is temperature control (or sensible load). When selecting and sizing an HVACD system for plants to thrive, it’s all about the latent load, plant transpiration and VPD. Excess humidity is roughly twice as difficult to remove as excess heat from lights, so an effective system needs to be designed as a dehumidifier first and an air conditioner second. Integrated dehumidification needs to be at the beginning of every HVAC conversation, and a primary focus of every system.

The benefits of including dehumidification as a critical component

To maximize plant vitality, two fundamental components to understand are transpiration and VPD. Put simply, VPD is the humidity difference (or deficit) between the inside of a leaf and the environmental conditions surrounding that leaf. It is this humidity difference that draws water from the roots of a plant, through the stem and out of the leaf tissue, otherwise known as transpiration. This process is critical to photosynthesis and optimizing plant production, and it’s all directly related to the levels of humidity in a given room. As humidity is drawn out of the leaf, dehumidification must be used to remove the humidity from the environment and maintain appropriate VPD levels. Without dehumidification, humidity builds inside the room, plant growth and plant health are negatively impacted, and conditions become ideal for pests and pathogens.

Properly-designed dehumidification creates consistent and precise environmental conditions across the plant canopy, mitigating risk against issues like powdery mildew and botrytis. Well-executed dehumidification allows growers to control their VPD and drive plant health. At the end of the day, a stable climate sets a strong foundation of cultural control for a facility to maximize quality biomass while limiting crop loss associated with pest and pathogen issues.

Why does this all matter? Because properly sized and commissioned HVACD systems empower the cultivator to maximize production efficiency, reduce the risk of production downtime, and promote growth.

HVACD will change industry standards and best practices

Collectively updating the industry’s knowledge and understanding surrounding dehumidification highlights the true challenges of growing plants indoors, and the need for purpose-built equipment and controls that optimize the environment based on every stage of the plant life cycle. Plants are living organisms that have different needs at different times, and mechanical equipment should be designed and manufactured around this concept.

We can draw a comparison to this concept by looking at indoor horticulture lighting systems. When the industry began to develop new terms like Photosynthetic Photon Flux Density (PPFD), the phrase “PPFD for plants because lumens are for humans” came to be. Meaning that if we are measuring lumens, we are prioritizing people in the space as opposed to the plants. This same mindset should apply to all mechanical equipment involved in a cultivation facility.

Now that more scientific studies and data are becoming available on topics like plant transpiration, dehumidification, and VPD as a driving force in plant vitality, it is clear that there is a better way to think about climate control when applied to controlled environment horticulture. HVAC focuses on the sensible (or temperature) cooling that keeps people happy indoors, while HVACD focuses on the latent cooling (or moisture removal) that keeps plants happy indoors. Both are critical concepts that must be considered during the design of an indoor cannabis cultivation facility to ensure both people and plants are happy indoors.

Critical Dehumidification Requirements for other Rooms in an Integrated Cannabis Grow/Manufacturing Facility

Extending the discussion downstream of horticulture to other areas of the facility, humidity control plays a critical role in profitability, food safety, asset utilization, and operating efficiency.

Humidity control in the Curing Room and the awareness of any air exchange with building areas adjacent to Cure is important. More broadly, any room-to-room pressure differentials can transfer air with different humidity levels.

Food safety is enhanced by considering humidity control, usually dehumidification. Any cold surfaces below the dew point of the room can cause condensation, which can lead to microbiological growth. Room environments controlled so that the water activity (aW) of the cannabis is maintained between 0.55 and 0.65, will also help limit mold growth and the associated mycotoxins.

In many cases, there are special dehumidification requirements, such as in an equipment drying room after warewashing, or to dry out a room and return it to operation after washing and sanitizing. HVACD designers need to coordinate closely with process or manufacturing specialists to be aware of any process exhausts, combustion air requirements, or high outside air exchanges. That additional outside air and the humidity carried in with it, must be considered.

And for Marijuana Infused Products (MIPs), specifically gummies and chocolates, the primary food safety control is low water activity, rather than a robust kill step, so precise humidity control is again a critical issue.

Even further, packaging machinery operates more efficiently if the flow characteristics of the cannabis are a key operating parameter. Moist cannabis will adhere to machinery and create other problems that slow run rates and cause downtime. This problem can occur with any weight fillers or the pre-roll machines.

All told, moisture can be both your friend and foe in a wide variety of cannabis endeavors. The ability to maintain the appropriate relative humidity, in addition to temperature, in each different type of room in a cannabis production facility is a key factor in a successful operation.

The Facilities Design Committee (FDC) focuses on providing NCIA members and regulators a framework and information about facilities design options through which legal producers can plan for GMP level production as the market transitions from a state to a federally regulated industry.

by NCIA’s Facilities Design Committee

by NCIA’s Facilities Design Committee

Follow NCIA

Newsletter

Facebook

Twitter

LinkedIn

Instagram

News & Resource Topics

–

This Just In

Committee Blog: Cannabis and Cardiovascular Disease

Rooted in Community: Fox Rothschild