Member Blog: The Importance of Storing Cannabis Properly

Cannabis is affected by humidity.

Yes, cannabis is definitely affected by humidity. Cannabis plants are sensitive to changes in temperature and humidity levels, both during cultivation and after harvesting.

During cultivation, cannabis plants need a specific range of temperature and humidity levels to thrive. Too much humidity can lead to the growth of mold and mildew, while too little humidity can cause the plants to dry out and become brittle.

After harvesting, cannabis buds need to be dried and cured to preserve their quality and potency. During this process, it is important to control the humidity levels to ensure that the buds dry slowly and evenly. If the humidity levels are too high, the buds can become moldy, while if they are too low, the buds can dry out too quickly and lose their potency.

In addition, the humidity level can also affect the storage of cannabis. If the humidity levels are too high, it can cause the buds to become moldy, while if they are too low, it can cause the buds to become brittle and lose their flavor and potency.

Therefore, it is important to control the humidity levels during the cultivation, drying, curing, and storage of cannabis to ensure that the buds are of high quality, potent, and safe for consumption.

How can dry cannabis lose potency?

When cannabis is dried and cured, it naturally loses moisture. However, if the cannabis becomes too dry, it can begin to lose potency.

This is because the active compounds in cannabis, such as THC and CBD, are stored in the trichomes on the surface of the buds. When the buds become too dry, the trichomes can become brittle and break off, causing the loss of these valuable compounds.

In addition, when cannabis becomes too dry, it can also affect the flavor and aroma of the buds. The terpenes, which are responsible for the characteristic smells and tastes of different strains, can degrade over time if the buds are too dry.

Therefore, it is important to store cannabis at the correct humidity levels to ensure that it stays fresh and potent. The ideal humidity range for storing cannabis is between 59% and 63% relative humidity. If the buds become too dry, you can try to rehydrate them by adding a humidifying device, such as a moisture pack, to the storage container. However, it is important to be careful not to add too much moisture, as this can cause the buds to become moldy or develop other quality issues.

Cannabis potency versus humidity

The potency of cannabis can be affected by humidity levels. When cannabis is stored at a high humidity level, it can cause the breakdown of THC and other cannabinoids, decreasing potency. On the other hand, if cannabis is stored at a low humidity level, it can cause the buds to become dry and brittle, which can also lead to a decrease in potency.

Therefore, it is important to store cannabis in a controlled environment with the appropriate humidity level. This can be achieved using specialized storage containers, such as airtight jars or humidors, designed to maintain a consistent humidity level. It is also important to monitor the humidity levels regularly and adjust as necessary to ensure that the cannabis stays fresh and potent.

Cannabis taste versus low humidity

When the terpenes are lost, the flavor of the cannabis can become harsh, bitter, or stale. This can make the smoking experience less enjoyable and may also indicate a decrease in potency.

If the buds have become too dry, it is possible to rehydrate them by adding a humidifying device, such as a moisture pack, to the storage container. However, it is important to be careful not to add too much moisture, as this can cause the buds to become moldy or develop other quality issues.

Member Blog: What’s in Your Garden? Identifying, Preventing, and Exterminating Pests

by Ashlyn East and Angel Fernandez, MyFloraDNA

Unfortunately, there are a variety of insects with the potential to damage the majority of your cannabis plants. Before we can fight back, we must be able to identify each symptom an insect may leave behind. Symptoms often vary amongst individual pests allowing us to identify them and treat the plant accordingly. This blog serves to highlight some of the biggest threats to cannabis gardens, including the following insects:

- Aphids

- Spider Mites

- Fungus Gnats

- Thrips

An aphid is a soft-bodied insect with a piercing-sucking mouthpart, allowing it to access a plant’s vascular system and steal its nutrients. They are visible to the naked eye but come in various colors, sometimes blending into the plant and making them hard to spot.

So, how can we know if aphids are present in our cannabis plants? According to Ryan Douglas, author of “Playing Plant Detective: How to Identify Insect “Fingerprints,” these insects often leave behind a smokey mold or “sooty mold,” consisting of a black or brown fungal disease. Aphids are mainly attracted to the protein within the sap of the plants, so the rest of the sugars in the sap pass through their body and are left behind on the leaves. This forgotten waste is known as honeydew and does not stay forgotten for long as ants are highly attracted to it. With this in mind, some other signs to be aware of are the collection of ants and left-over honeydew.

For preventative and exterminate measures, regularly check your plant for symptoms of the pest, remove and spray off as many bugs as possible, and also consider insecticide soaps and sprays that will not harm your plants.

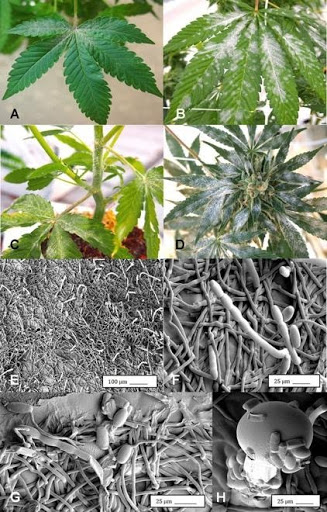

Figure 1. Aphids in different phases of life

Spider Mites

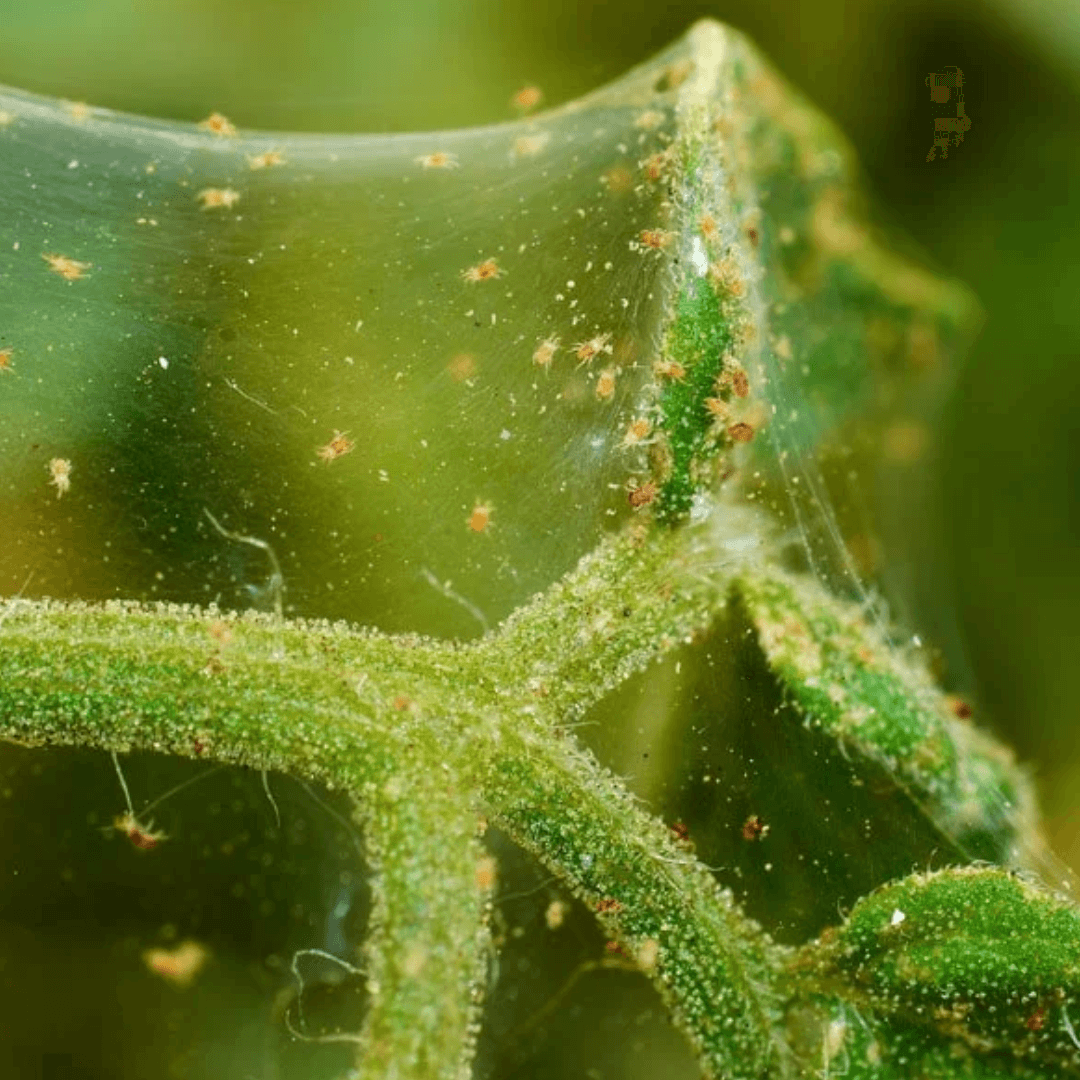

Spider mites are smaller than aphids but still visible to the naked eye. They are often dark red, orange, or brown. Spider mites also have tiny piercing mouths that allow them to feed on nutrients obtained from the plant leaves.

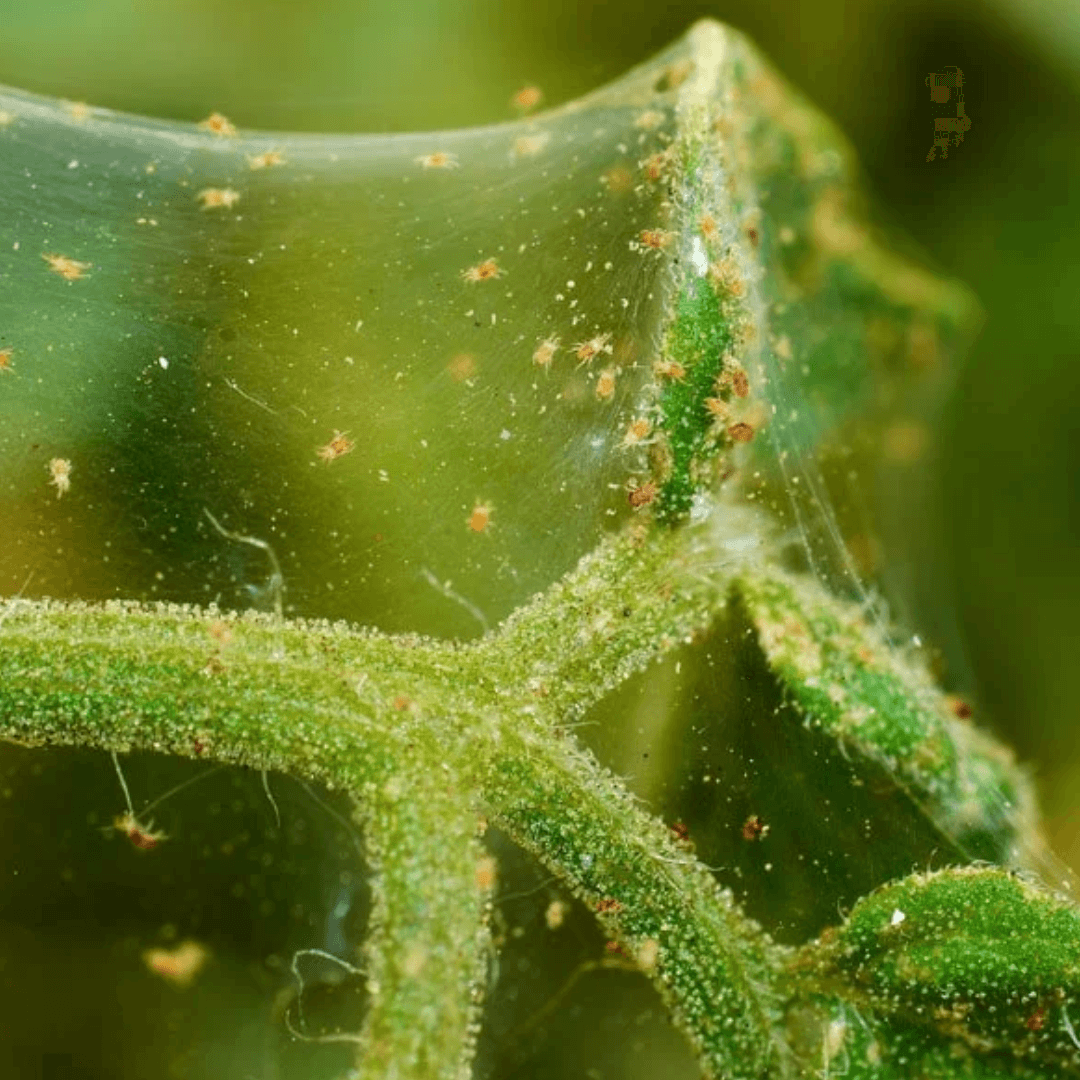

It can be hard to spot their presence in the early stages, as they tend to remain under the plant leaves until their population expands. Once the populace has reached a larger capacity, spider webbing will be present along the top of the plant canopy. In addition, the mites will often leave behind little white specks on the top of the leaf. The idea is to spot the mites before webbing occurs; this can be done by frequently and thoroughly examining your plants.

Early detection of spider mites is vital for exterminating and preventing their growth. According to Nebula Haze, author of “Cannabis Pests, Bugs, & Viruses,” these mites quickly reproduce and gain immunity to extermination methods. Therefore, it is important to use multiple forms of extermination consistently to prevent their return.

Figure 2. Spider mite webbing on a cannabis plant

Fungus Gnats

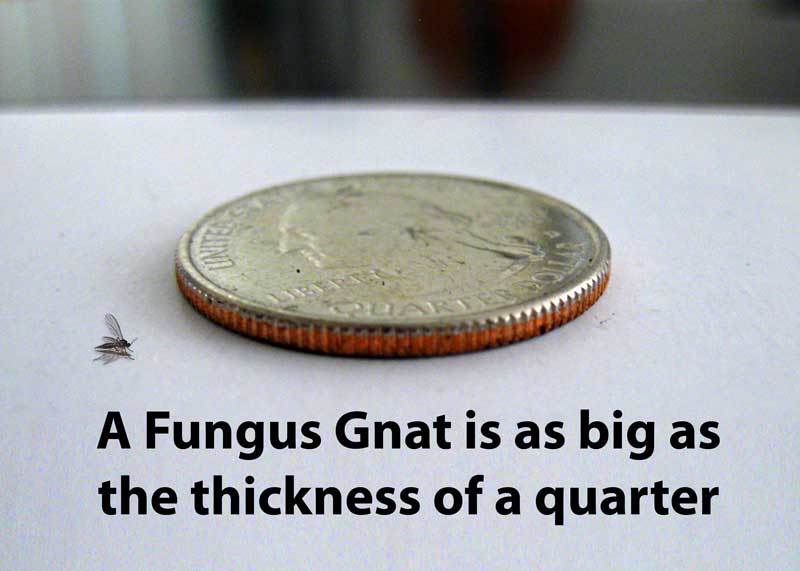

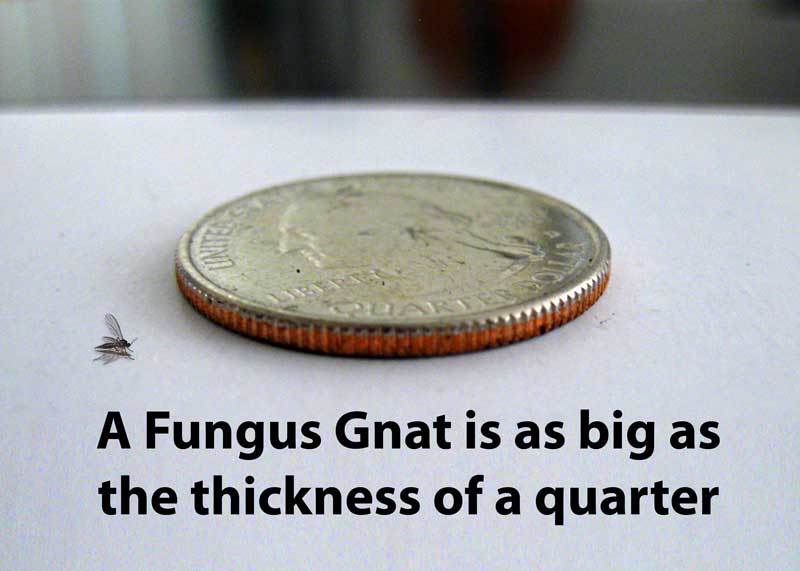

Unlike aphids and spider mites, fungus gnats primarily feed on plant roots. These gnats look like tiny black flies and can have quite harmful effects on plants. Not only are the flies feeding on the roots, but the larvae destroy root hairs and young roots of the cannabis plants (Haze, 2022).

Fungus gnats are not as easy to trace because their usual resting spot on the plant allows them to blend in with the dark soil and surface area. A more visible clue of “fungus gnats is the presence of their feces on the leaves, nursery pots, and grow benches” (Douglas, 2022). If there happens to be any flying bugs around the plant, that could also be a prominent symptom.

Ensuring prevention and extermination are possible from a variety of practices. Be sure not to over-water the plants, as gnats a more attracted to overly damp areas. It may also be helpful to hang sticky cards near your plants and, once again, utilize insecticide sprays when necessary.

Figure 3. Fungus gnat, in comparison to a quarter

Thrips

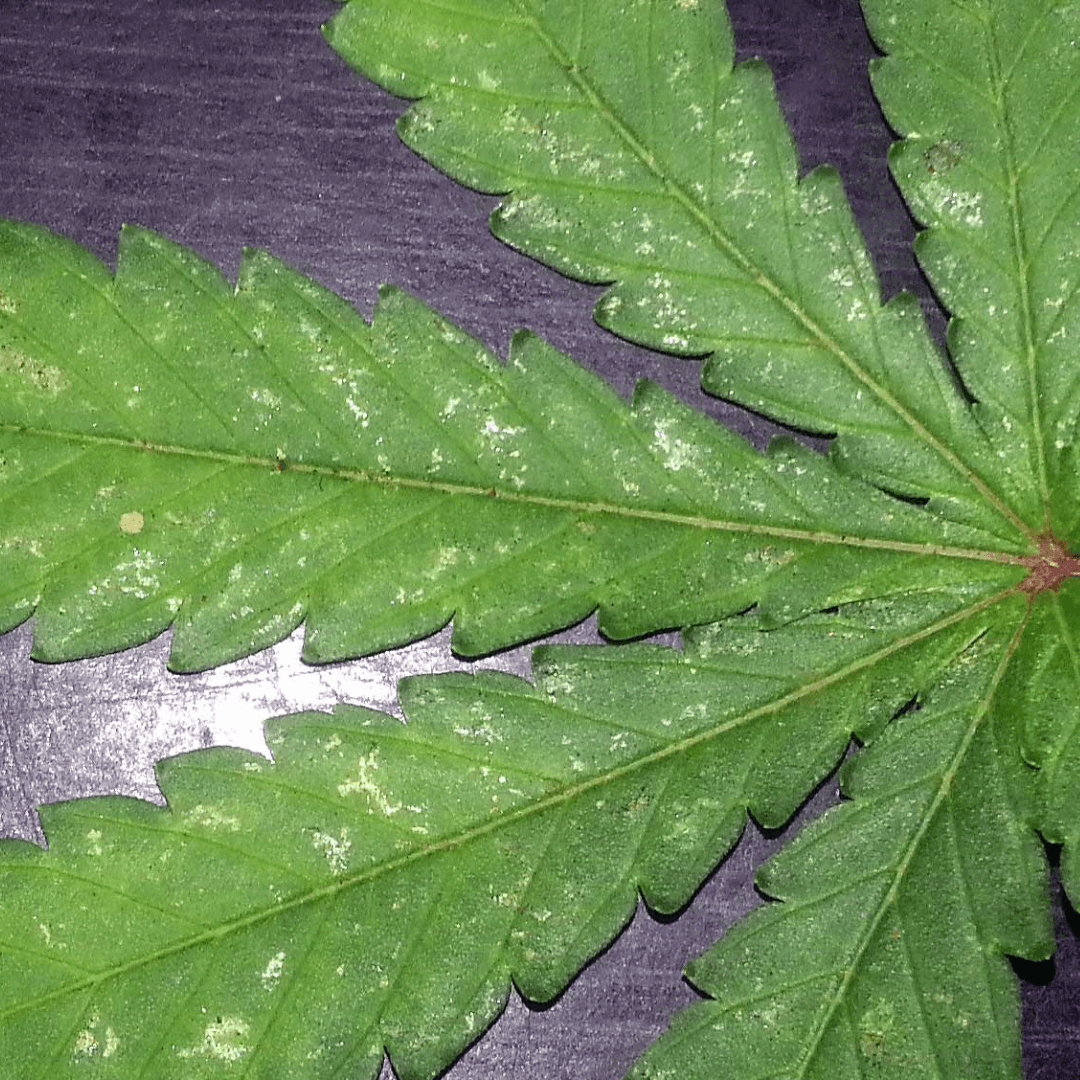

A thrip is yet another insect that raises a threat to the healthy growth of cannabis plants. “Adult thrips are small, fast-moving insects, while young thrips look like tiny unmoving pale worms on the leaves” (Haze, 2022). Depending on their stage of life, they could look a variety of ways. They often blend into the plant because of their color and will jump around if they feel threatened. These variables cause their extermination to be quite tricky.

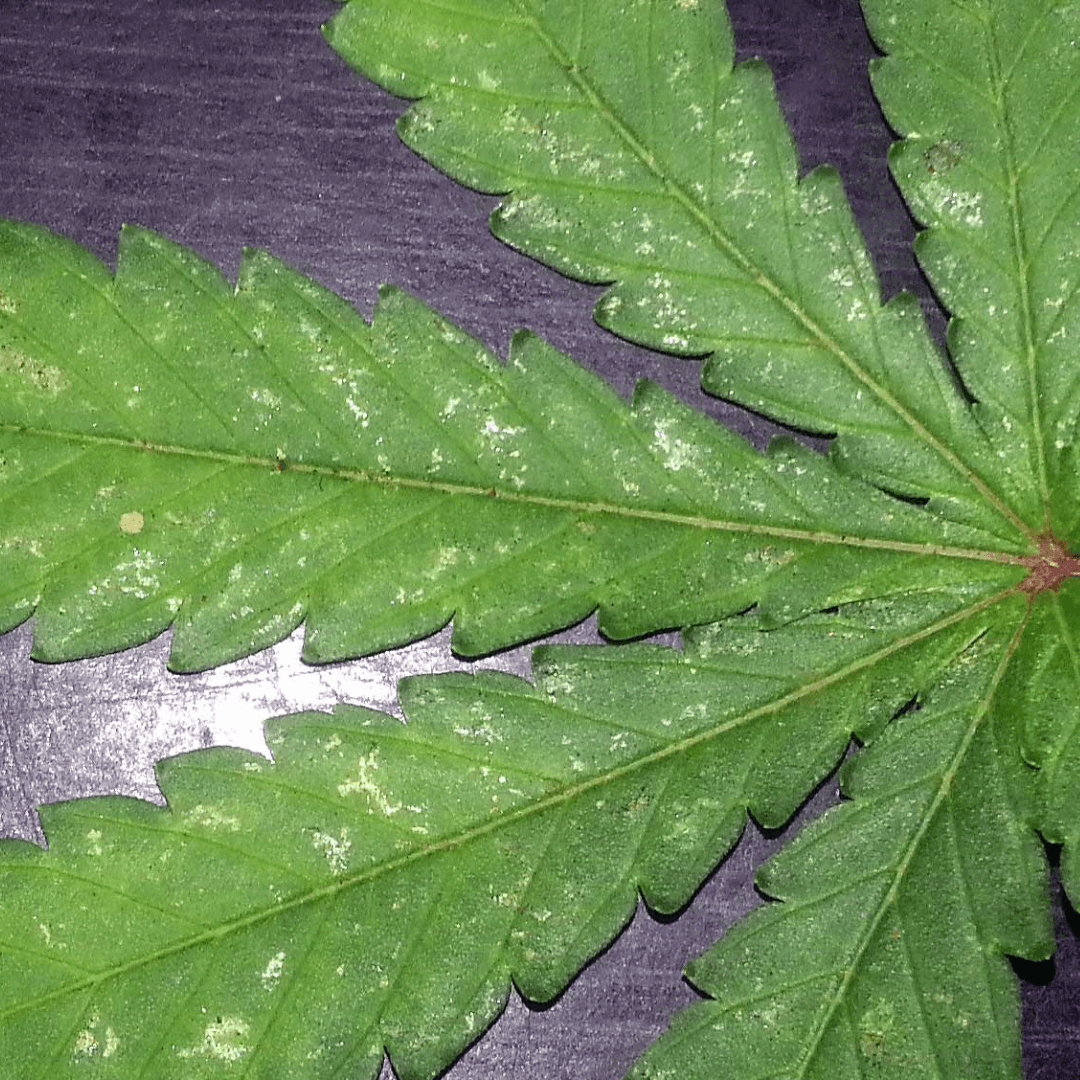

Thrips have small, piercing mouths like spider mites and aphids, but the leaves often look more scraped than pierced (Douglas, 2022). Douglas gives a great suggestion to test a plant for thrips. If you hold a white piece of paper under the suspected leaf and tap on the leaf, you will be able to see the thrips fall on the paper. As adults, they will typically appear as orange, brown, or yellow.

Figure 4. Thrip-damaged leaf

Examining your cannabis plants regularly makes the prevention or early diagnosis of pests a manageable task. As you examine your plants, keep in mind the range of symptoms that stem from various insects. In the end, if you happen to come across any harmful pests, be diligent in your extermination methods and find the necessary method according to the pest you discover.

References

- Haze, N. (2022, August 7). Complete pest guide – cannabis pests, bugs & viruses. Grow Weed Easy. Retrieved October 19, 2022, from https://www.growweedeasy.com/bugs-pests-symptoms-marijuana-grow

- Figure 1: https://content.ces.ncsu.edu/cannabis-aphid-in-industrial-h

Photographer: Whitney Cranshaw, Colorado State University, Bugwood.org

About MyFloraDNA: We are a genomic laboratory based in Woodland California, delivering modern genomics for the Cannabis Industry.

Our services include Trait detection (cannabinoid profile and sex/gender ID), Pathogen Detection, and Genetic Validation Services. We offer breakthrough solutions using the inner power of your plants.

Authors: Ashlyn East and Angel Fernandez

Angel Fernandez, CEO & Co-Founder at MyFloraDNA. “It is time to fill in the gap between DNA Sciences and Agriculture. MyFloraDNA is willing to show the huge opportunities that exist for modern genetics in agriculture. Now, it is time for another agricultural revolution”

Editor: Maria Zuccarelli

Committee Blog: The Asset We Wish We Knew Before 2020 – HACCP

by Trevor Morones, Darwin Mallard, Liz Geisleman

by Trevor Morones, Darwin Mallard, Liz Geisleman

NCIA’s Cannabis Manufacturing Committee

Read on for insight and guidance for the vitally important topic of preventing, eliminating, or reducing microbial growth in cannabis edibles and packaging.

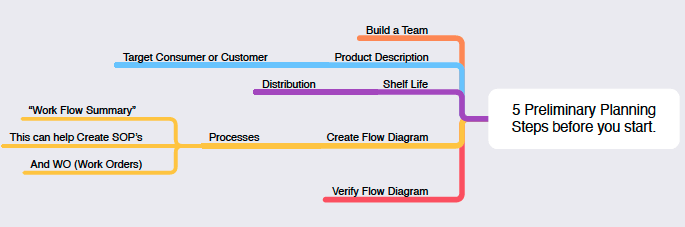

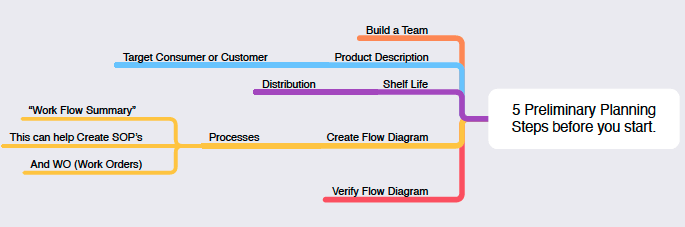

It all starts with the HACCP (Hazard Analysis Critical Control Point) Principles. Gather your team to share the five preliminary steps of HACCP and develop a plan (figure 1). This management system was launched by Pillsbury along with NASA and the U.S. Army for food safety in space exploration in the 1960’s. Quality, safety and efficacy is obtainable and sustainable with the HACCP discipline.

The objective is to PREVENT packaging from being a failure point and inhibit microbial growth in edible products. We know moisture (water activity), temperature, pH, and oxygen levels are primary microbial growth drivers.

HACCP is an asset, not an expense. Food is medicine for some, and cannabis products are medicine for many. Resin cannabis products (RCP) must be safe, consistent, and reliable products continuously. To generate those results, learn the HACCP mindset. Practice being an advocate with HACCP discipline displaying the actions written in the programs. It’s a system for cannabis safety that encourages operations to have Emergency and Business Continuity plans before disruptive events occur, e.g., natural disasters, pandemics, etc.

- Resin cannabis product – Any product, whether finished or a work in progress, containing or comprised of cannabis flowers or resins or both and includes, but is not limited to, the cannabis flowers and resins themselves, extracts/concentrates/derivatives thereof, and preparations therefrom.

- And can be further classified as Adult-Use or Medicinal-Use and subclassified as Topical-Use.

Creating such a plan is important because exposure to microbes may result in allergic symptoms such as sneezing, coughing, wheezing, nasal congestion, and watery or itchy eyes. Consumers using cannabis products as medicine, such as cancer patients on chemotherapy, are even more susceptible to harm caused by microbes. Thus, it is critical to ensure your products do not have microbial growth.

This is not only a health concern, but the financial impacts can be detrimental. How much did the February 2021 Canadian infused gummy recall cost? More than 330,000 packages of THC infused gummies, worth approximately 8.2 million Canadian dollars, were lost. Overhead costs go above and beyond. The global cannabis industry must learn from industry events such as this.

Effective HACCP management system ensures control. Empower your team through education and training on discipline of HACCP. Take the infused gummy recall from February 2021 as an example where cross-contamination, improper employee hygiene, and package permeability were failure points that led to loss of control. Lack of control during transport of the initially sterile packaging also contributes to contamination. Personal clothing worn by team members or visitors are also known sources of pathogenic fungus.

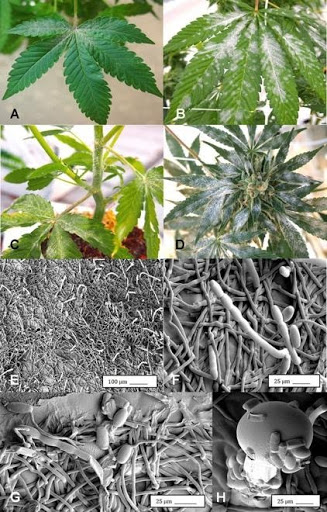

Best practice is to address preventive controls and reducing/mitigating risks. For example, consider installing two-way humidistatic control devices in packaging, such as desiccant packs, to maintain water activity (Aw) in acceptable ranges to mitigate microbial growth. Reducing moisture prevents powdery mildew caused by Golovinomyces Cichoracearum (figure 2).

A great resource to mitigate risks can be found in the ASTM D37; Standard Guide for Cleaning and Disinfection at a Cannabis Cultivation Center; Aw ASTM Standards for Cannabis Flower: D8196 – Standard Practice for Determining Water Activity in Cannabis Flower; and D8197 – Standard Specification for Maintaining Acceptable Water Activity Range for Dry Cannabis Flower.

Sanitary environments are critical from seed to sale.

Figure 2, Right. Powdery mildew development on leaves, stems, and flower buds of Cannabis sativa, caused by Golovinomyces cichoracearum. 2

Use the principles of HACCP to guide and maintain the integrity of your work. Each principle builds on the next to create a solid foundation to build and operate a safe and consistent management system. Establish storage conditions in your control and transport; determine the temperature and humidity for each product type (gummies do not tolerate heat, and certain ingredients are sensitive to humidity which could change the potency). This includes evaluating the stability of each of the ingredients when in final product form (how long do they remain potent).

Depending on the ingredients used, i.e., the formulation, gummies can take on or reject water. Most typically let out the water, then that water has nowhere to go (trapped in the packaging), and the product molds. This is why commercially produced gummies are coated in wax, literally to trap the water inside the product. Inadequate gummy formulations lead to water permeability; change in cannabinoid content is the least of the concerns.

General chapter 659 on Packaging and Storage requirements published by the USP (United States Pharmacopeia and the National Formulary, USP–NF) is a great resource. Though not all cannabis products may be for the medical market, using the standards of excellence from the USP is the best way to minimize product failure and help ensure consumer safety. Packaging 659 states that packaging materials must not interact physically or chemically with a packaged article in a manner that causes its safety, identity, strength, quality, or purity to fail to conform to established requirements.

Empower your cross-functional team to apply and implement HACCP through your organization. In doing so, you will have the discipline and tools to mitigate risks and prevent costly downtime. Your consumers benefit by having safer, consistent, and quality products. Finally, collect the data and share the story. We all need to drive improvement and produce safe consistent products for our consumers. HACCP systems are a tried-and-true tool to achieve this.

Please note that prerequisite programs such as current Good Manufacturing Practices (cGMPs) are an essential foundation for the development and implementation of successful HACCP plans. This article is intended to level up your current manufacturing processes and mitigate your exposure to potential recall or unsafe products in the marketplace.

For resources on how to establish an effective HACCP system and other quality management related tools, consider adopting the best practices defined in ASTM D8250 – Standard Practice for Applying a Hazard Analysis Critical Control Points (HACCP) System for Cannabis Consumable Products and/or following the guidelines provided in ASTM D8222 – Standard Guide for Establishing a Quality Management System (QMS) for Consumer Use Cannabis/Hemp Products and ASTM D8229 Standard Guide for Corrective Action and Preventive Action (CAPA) for the Cannabis Industry.

Committee Blog: Future-Proofing Your Business – How Adopting Industry Standards Improves Your Bottom Line and Reduces Your Risks

by NCIA’s Facilities Design Committee

By developing and adopting standards now, operators in the cannabis space can avoid unnecessary future expenses they might incur when needing to rework established facilities to meet upcoming federal standards or third-party compliance

Upton Sinclair’s The Jungle in 1905 led to the Pure Food and Drug Act in 1906. The food sector has matured through additional governmental regulations, industry-led initiatives, consumer and trade guidelines and standards, and more recently, the Food Safety Modernization Act. Over one hundred years of progress helped to ensure what is arguably the safest food supply in the world. By comparison California, in 1996, 24 years ago, legalized Medical Cannabis. Since then, 36 states have legalized cannabis for medical or adult use. Confusingly, that is 36 different sets of regulations, none harmonized. And no consensus on how FDA will regulate cannabis when it is descheduled.

But investors and producers in the cannabis sector are seeking direction on how to future proof their businesses so they can manage the transition from fragmented state-level regulations to rigorous federal oversight. Developing and adopting cannabis industry best practices may be the greatest insurance available.

NCIA’s Facility Design Committee is one of the few groups beginning this effort. The group has representatives from operations, regulatory compliance, quality, equipment vendors, design and construction, and allied industries.

Standards can focus on several areas. Because the cannabis industry deals with substances that are ingested into the human body, standards that support consumer health and safety are paramount. Much of the current practice in the food sector, organized under the topic of current Good Manufacturing Practices (GMPs), can port over to Cannabis with some adjustments. These practices protect consumers and your brand. GMPs have, as a foundation, many aspects of facility and process design, but standards for these don’t yet exist. However, by developing and adopting standards now, operators in the cannabis space can avoid unnecessary future expenses they might incur when needing to rework established facilities to meet upcoming federal standards or third-party compliance. They also can control their own destiny, in effect, by establishing approaches that later can be considered as regulators write the rules in the future.

As operators themselves, a number of our committee members have felt the direct impact of product recalls due to a lack of clear delineation at the intersection of cannabis and food safety regulations. Depending on the scope of the recall, a company can be crippled by not properly understanding and adhering to a common set of standards across the industry, especially when concerning safe food handling practices and similar regulations that control consumable product manufacturing. For example, one of our committee members had to recall a batch of infused gummies because public health regulators used safe food handling regulations to determine that the gummies were exposed for too long in a potentially contaminated environment during the setting process. Had the operator adhered to standards commonly used in food production, they would have avoided the costly impact of the product recall. With nearly 15% of flower failing tests for yeast and mold in Colorado, the cannabis industry has become no stranger to costly recalls.

Standards not only minimize risk to the consumer and the business, but also improve quality and consistency. Improve employee NPS (Net Promoter Scores). Reduce cost and production downtime. Increase the inherent value of the business. And offer a brand message that increases sales.

Nearly all related industries follow best practices, known as cGMPS (current Good Manufacturing Practices), which can be adopted for our industry. If we look to examples from the food sector, you find mature and professional regulations at the federal level and experienced inspectors from USDA, FDA and state departments of Health or Agriculture, as well as global standards from the International Organization for Standardization (ISO) and the World Health Organization (WHO), initiatives from trade customers such as Global Food Safety Initiative (GFSI), equipment certifications from European Hygienic Equipment Design Group (EHEDG), NSF International, and 3-A Sanitary Standards. This constellation of resources is not yet published for the cannabis sector.

But the work is beginning with NCIA’s Facility Design Committee. Groups including 120-year-old ASTM International have established the D37 Committee on Cannabis, Safe Quality Foods (a GFSI scheme) is working on a Cannabis Supplement program, and Underwriters Laboratories (UL) and ISO recently announced the launch of a standards initiative at the end of November 2020.

Join us in this exciting journey. Become involved, and stay aware of and ahead of the pending regulations. We don’t have 114 years to get this right!

The Facilities Design Committee (FDC) focuses on providing NCIA members and regulators a framework and information about facilities design options through which legal producers can plan for GMP level production as the market transitions from a state to a federally regulated industry.

Member Blog: 7 Places You’ll Find Mold In Most Cannabis Grows

by Bernie Lorenz, PhD, Chief Science Officer for ProKure Solutions

Want Clean Cannabis? Identify Mold Pain Points.

In the battle against mold, there are three critically important questions.

- Where is the mold coming from?

- How did mold get there?

- How did the mold travel to where it grew?

Answering these questions gives growers the power to mitigate mold, and the ability to pass total yeast and mold tests.

Know Thy Enemy

It helps to first understand what you’re up against. Understand first and foremost that mold is a living thing that starts and ends somewhere. Its spores travel to reproduce, just like a plant.

And it needs the right environment to flourish. Moisture and temperature have the biggest impact. But hosts that help it travel are also critical.

Process Over Point

Most indoor and greenhouse grows have dozens, if not hundreds of people working across the organization. From back office to packaging to production – you have people and places that impact the air quality and can act as hosts, ultimately, impacting spore counts.

These hundreds of interchangeable parts make it difficult to figure out the source of mold, so it’s critical to see it as a process.

Break your facility into seven core parts of a process, and start digging. Not literally, of course, but as a scientist would. Examine what might cause the issues by looking at variables and constants.

Look at these seven locations:

- Mother Plants

- Cuttings from Mother Plants (clones, propagation)

- Vegetative Growth

- Flower Growth

- Trim Rooms

- Immediate postharvest

- Sometimes after dry and cure

- Dry Rooms

- Cure Space

Follow the plant through those places and test regularly to see where moisture or cross-contamination may be occurring.

This is a painstaking process, make no mistake. Mold develops over time, so you’ll need to spend weeks or months tracking the lifecycle of the plant.

You’ve Solved The Riddle, Now Solve The Problem

Of course, once you find the sources, mitigation through a solid Integrated Pest Management (IPM) program is critical. There are many methods for that, from cleaning and disinfection to HEPA filters, and more. You’re not in this fight alone, either. You can call solutions providers like ProKure for help or find a Certified Industrial Hygienist in your area.

Whatever you choose to mitigate with, just remember to start with the answers to those core questions. Any program will be much more effective with those in mind.

Bernie Lorenz, PhD, is Chief Science Officer for ProKure Solutions, where he applies an advanced chemistry background and passion for sustainability to make ProKure products approachable to cultivation professionals. As one of the industry’s most seasoned experts on ClO₂, Dr. Lorenz recently led the effort as technical contact for a new ASTM International standard aimed at establishing cleaning and disinfecting protocols for indoor and greenhouse cannabis cultivation facilities. Dr. Lorenz earned both his PhD and Masters in Inorganic Chemistry from New Mexico State University.

Bernie Lorenz, PhD, is Chief Science Officer for ProKure Solutions, where he applies an advanced chemistry background and passion for sustainability to make ProKure products approachable to cultivation professionals. As one of the industry’s most seasoned experts on ClO₂, Dr. Lorenz recently led the effort as technical contact for a new ASTM International standard aimed at establishing cleaning and disinfecting protocols for indoor and greenhouse cannabis cultivation facilities. Dr. Lorenz earned both his PhD and Masters in Inorganic Chemistry from New Mexico State University.

by Trevor Morones, Darwin Mallard, Liz Geisleman

by Trevor Morones, Darwin Mallard, Liz Geisleman

Bernie Lorenz, PhD, is Chief Science Officer for ProKure Solutions, where he applies an advanced chemistry background and passion for sustainability to make ProKure products approachable to cultivation professionals. As one of the industry’s most seasoned experts on ClO₂, Dr. Lorenz recently led the effort as technical contact for

Bernie Lorenz, PhD, is Chief Science Officer for ProKure Solutions, where he applies an advanced chemistry background and passion for sustainability to make ProKure products approachable to cultivation professionals. As one of the industry’s most seasoned experts on ClO₂, Dr. Lorenz recently led the effort as technical contact for