By Taylor Robinson – R&D Manager and Chief Chemist, Silver Bullet Water Treatment & Kyle Lisabeth – Director of Horticulture Business Development, Silver Bullet Water Treatment

Condensate capture for reuse is an intriguing new application within the controlled environment horticulture space. Addressing both environmental impacts and regulatory requirements, capturing and reusing condensate has many attractive benefits. However, several key questions have appeared surrounding the topic of condensate water capture and reuse applications that have slowed its adaptation in many facilities. In this article, we discuss common questions and concerns associated with condensate reuse and how each may be addressed with adequate, customized treatment processes.

Condensate water is generated by a number of processes within a controlled environment agriculture facility. Most commonly, dehumidification and HVAC systems are the primary sources of condensate water. The source of water and collection system plays a significant role in condensate water quality and associated concerns when considering reuse.

Why is collecting and reusing condensate water a good option?

- Recycling available water streams reduces the amount of fresh water required and offsets associated costs.

- Recycling minimizes discharges and waste. Coming regulations will require extensive discharge limits.

- With adequate monitoring and treatment, risks may be greatly reduced, maximizing benefit.

Contamination – Don’t Let One Bad Apple Ruin the Bunch

In general, condensate water is low in Total Dissolved Solids (TDS)/Conductivity and is generally very clean. pH is typically low as carbon dioxide readily absorbs into solution (pH 5.5-6.5 range). Contaminates are easily introduced based on what the water contacts during collection and distribution. Volatile Organic Compounds (VOCs) and other organics can be absorbed and provide “food” for microbial proliferation – especially if the condensate is pooled and stored for extended periods. Metals leaching from dehumidification equipment and/or from dust/air pollutants also may accumulate. Identifying and managing emerging contaminates is crucial to successfully mitigate risk and maximize value when reusing condensate water.

Microbes and Organics

By themselves, most organics potentially found in condensate water pose little threat. However, organic (carbon-based) pesticides, foliar sprays, etc. have the potential to accumulate in exposed condensate water and could lead to downstream issues. Organics also provide a potential carbon source for various microbial populations to proliferate. This can create biosecurity challenges, plant disease and challenge existing water treatment processes. Microbes are ubiquitous in nature and although pathogens are presumed to make up less than 1% of the known microbial kingdom, contamination remains a threat. Airborne bacteria, viruses and fungal spores can be introduced to a condensate water system through its condenser plates. Microbial proliferation and the formation of biofilms on wetted surfaces downstream of dehumidification equipment can result in elevated levels of total and pathogenic microbes.

Heavy Metals

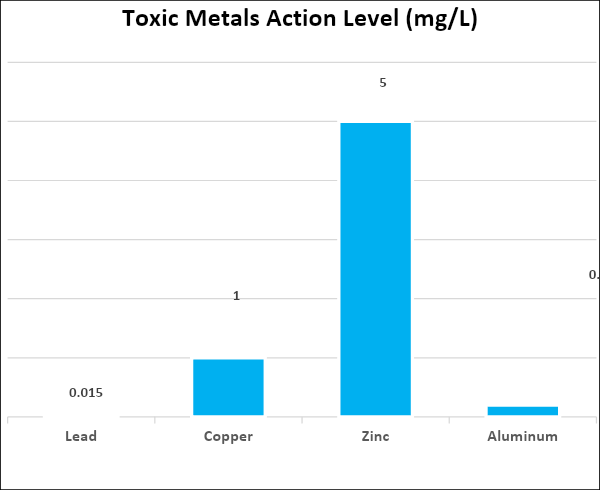

Heavy metals including lead, zinc, aluminum, and copper may be a concern if leaching from dehumidification equipment occurs. Soldered joints in copper tubing, for example, may introduce lead to condensate water. In that case, mechanical joints/brazed joints would be preferred. Aluminum, copper, and zinc may be stripped directly from metal surfaces as part of generalized corrosion. Even at relatively low levels, some metals, dissolved contaminates and other corrosion byproducts can bioaccumulate in plants resulting in compounded issues, including phytotoxic effects.

Water Treatment & Management

In many situations, the use of recaptured condensate water is a viable option to supplement make-up water demand and reduce waste discharge. Treatment prior to reuse is recommended to condition the condensate water to ensure water system stability over time and to prevent potential treatment and operational challenges that could otherwise arise.

Available treatment processes include Advanced Oxidation Process (AOP) gas and UV for disinfection, adsorptive media for dissolved organics and various other filtration processes for metals and other contaminate removal. The extent and type of treatment varies based on specific water challenges and end goals.

Baseline and routine subsequent water testing and monitoring is key to maintain a proactive approach to water management. Integrating smart water management programs limits waste, improves logistics, saves money, protects the environment and allows for current and emerging regulatory compliance. Equally important is choosing the right technical partner to help develop and implement your smart water management program.

Taylor Robinson is the Research & Development Manager and Chief Chemist for Silver Bullet Water Treatment with expertise in molecular and cell biology, general water chemistry, microbiology, and industrial (oil and gas) water treatment and reuse processes/chemistries. For the past 4 years, Taylor has led, conceptualized, organized, and completed numerous Silver Bullet research and development projects related to water treatment for the livestock, cooling water, horticulture, aquaculture and data center industries. Taylor joined Silver Bullet in 2016 and has been a key contributor to the advancements in the company’s technology and research base.

Taylor Robinson is the Research & Development Manager and Chief Chemist for Silver Bullet Water Treatment with expertise in molecular and cell biology, general water chemistry, microbiology, and industrial (oil and gas) water treatment and reuse processes/chemistries. For the past 4 years, Taylor has led, conceptualized, organized, and completed numerous Silver Bullet research and development projects related to water treatment for the livestock, cooling water, horticulture, aquaculture and data center industries. Taylor joined Silver Bullet in 2016 and has been a key contributor to the advancements in the company’s technology and research base.

With over 15 years’ experience, Kyle Lisabeth has been focused on improving water management programs across multiple industries, with a central focus of treating water for reuse applications. Kyle attended the University of Texas – Austin, and upon graduation with a BS in Biology and Environmental Sciences, gained years of international water management experience in both North and South America. Since establishing Silver Bullet’s Horticulture Division, Kyle has exponentially grown the business unit’s install base and cultivated a nationally known water treatment brand for many controlled environment agriculture applications, including cannabis.

With over 15 years’ experience, Kyle Lisabeth has been focused on improving water management programs across multiple industries, with a central focus of treating water for reuse applications. Kyle attended the University of Texas – Austin, and upon graduation with a BS in Biology and Environmental Sciences, gained years of international water management experience in both North and South America. Since establishing Silver Bullet’s Horticulture Division, Kyle has exponentially grown the business unit’s install base and cultivated a nationally known water treatment brand for many controlled environment agriculture applications, including cannabis.

Follow NCIA

Newsletter

Facebook

Twitter

LinkedIn

Instagram

–