Justine Charneau, Head of Cannabis Industry Sales, Eagle Protect

Cannabis workers who regularly wear disposable gloves have every right to be surprised – shocked even – that the products they’re pulling from an unopened box may be contaminated with any number of harmful pathogens and chemicals, yeast species, or a variety of distinct genera of fungi – all of which are capable of leading to costly product recalls. After all, these gloves just came out of a brand new box, completely unused. But that’s precisely what a multi-year metagenomic testing and analysis study recently uncovered about contamination threats on the interior and exterior surfaces of nitrile gloves.

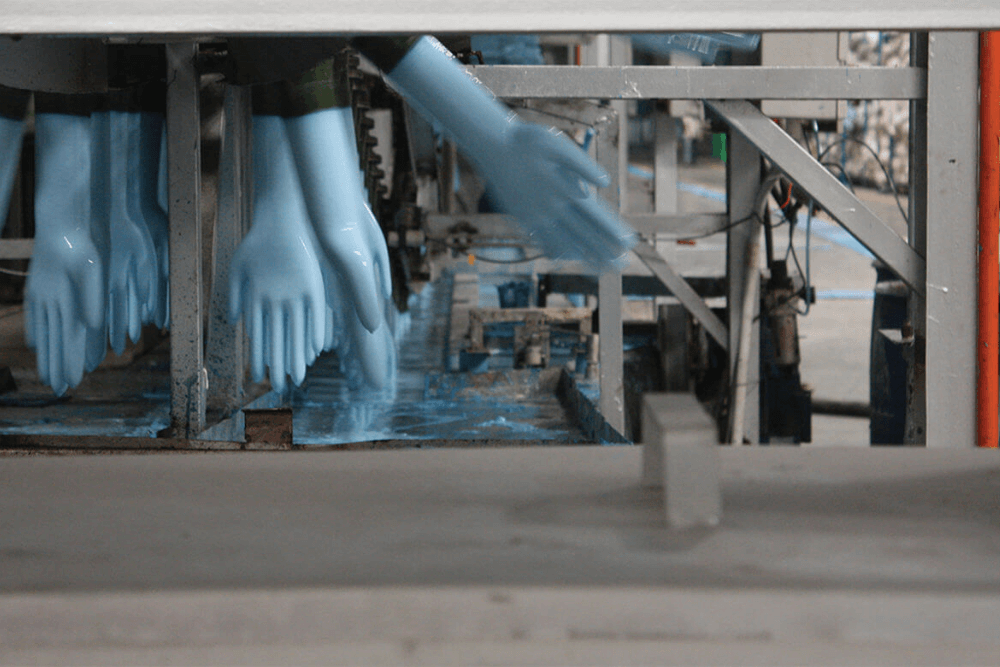

The threats were present because the gloves were contaminated prior to packing and shipping them to your supplier. contamination occurs during the manufacturing stage due to glove manufacturers operating in sub-standard facilities, compounded by their efforts to cut corners and save costs during the production process. Below, we trace the arc of surface pathogen transmission – from its primary source to the end user.

Polluted Water Sources

How does contamination first enter the manufacturing supply chain? In both a figurative and literal sense – the biggest threat comes from upstream. Many overseas glove manufacturers aren’t operating with clean water sources, using putrid water which can be polluted with agricultural fertilizers and pesticides, as well as industrial wastewater and both human and animal sewage. Glove manufacturing uses an abundance of hot water in several phases of production, so polluted water sources contribute to contamination.

Inferior Raw Materials

Contamination can be introduced with poor quality raw materials. While it saves money, gloves produced with cheap materials can include toxic chemical compounds and other unsafe filler ingredients. Chemical contamination in gloves caused a recent cannabis recall. Inferior raw materials can also greatly decrease the durability and performance of the glove and can easily cause skin irritations for the glove user.

Former Cleaning & Drying

The threat of contamination is further compounded when manufacturers fail to raise the water tank temperatures high enough to kill microbes. Formers, the ceramic, hand-shaped molds used in glove manufacturing, undergo cleaning processes involving hot water and bleach. When the water temperature and chlorine concentration aren’t high enough, or, if the wash water and brushes are not thoroughly cleaned between production stages, microbial contamination can occur.

Inadequate Drying Procedures

Following the former cleaning and drying stage, gloves are vulcanized (heat-treated) in ovens to both strengthen and elasticize them. Gloves are then subjected to the drying process in large industrial ovens that also require routine cleaning. But for some glove manufacturers , simply shortening the drying cycle in tumblers that aren’t routinely cleaned can slash utility costs. The result? These inadequate drying procedures leave products damp, where they’re much more susceptible to airborne microbial contamination.

The Packing Room

After the drying stage, gloves are boxed. New tech manufacturing does this automatically, however, gloves can also be packaged in unhygienic or unsanitary open-air packing rooms where human skin contaminants, including fecal matter, can contaminate gloves. These unsanitary conditions can further expose gloves to contamination, right before they’re packed into boxes.

As you can see, each of the production stages in the glove manufacturing process comes with its own set of contamination risks. If you’re inclined to think that government and industry regulations, oversight, and compliance requirements are designed to prevent such contamination risks, you’re going to be sorely disappointed. But that’s a topic for the next blog in our contamination series, so stay tuned.

Follow NCIA

Newsletter

Facebook

Twitter

LinkedIn

Instagram

–